Posts By Megan Johnston

Filter Press Manufacturers in USA

Filter press manufacturers in the United States play a vital role in the production of various products, including food, beverages, and pharmaceuticals.In this article, we will explore the top filter press manufacturers in the US, their products, and their services.

Top Filter Press Manufacturers in the USA

-

Jingjin manufacturer: Jingjin Manufacturer is a leading manufacturer of filter presses, valves, and other process control equipment. Their products are used in a wide range of industries, including food, beverage, and pharmaceuticals.

-

Waters Corporation: Waters Corporation is a global leader in the development and manufacture of laboratory equipment, including filter presses. Their products are used in research and development, quality control, and production processes.

-

Thermo Fisher Scientific: Thermo Fisher Scientific is a multinational corporation that provides a wide range of scientific instruments and consumables, including filter presses. Their products are used in various industries, including life sciences, healthcare, and environmental monitoring.

-

Spectrum Brands: Spectrum Brands is a leading manufacturer of filter presses, valves, and other process control equipment. Their products are used in a variety of industries, including food, beverage, and pharmaceuticals.

-

KSB Inc.: KSB Inc. is a leading manufacturer of filter presses, valves, and other process control equipment. Their products are used in a wide range of industries, including food, beverage, and pharmaceuticals.

Products and Services of Filter Press Manufacturers in the USA

Filter press manufacturers in the US offer a wide range of products and services, including:

-

Filter Presses: Filter presses are used to separate and concentrate liquids based on their physical and chemical properties. They are commonly used in the food, beverage, and pharmaceutical industries.

-

Valves: Valves are used to regulate the flow of fluids in various industries, including food, beverage, and pharmaceuticals.

-

Process Control Equipment: Process control equipment includes sensors, actuators, and other components that are used to monitor and control various processes.

-

Consumables: Consumables include filters, cartridges, and other components that are used to clean and maintain filter presses and other equipment.

-

Services: Many filter press manufacturers in the US offer services, including maintenance, repair, and calibration of their equipment.

Conclusion

Filter press manufacturers in the US play a vital role in the production of high-quality products in various industries. With the growing demand for efficient and effective filter presses, the industry is expected to continue growing in the coming years.

By understanding the top filter press manufacturers in the US, their products, and services, companies can make informed decisions about their equipment and operations.

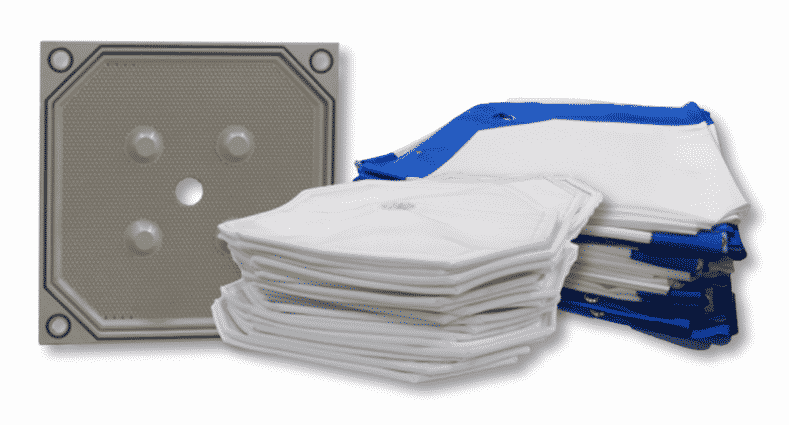

How to Choose the Proper Filter Press Cloths?

Are you tired of using the wrong filter press cloths for your industrial needs? Choosing the right filter press cloths can be a daunting task, but with the right information, it can be a breeze. In this article, we will guide you through the process of selecting the proper filter press cloths for your specific needs.

How to Choose the Proper Filter Press Cloths

Choosing the right filter press cloths is crucial for the efficiency and effectiveness of your industrial processes. Here are some tips to help you make the right choice:

Consider the Material

The first thing to consider when choosing filter press cloths is the material. Different materials have different properties that make them suitable for specific applications. Here are some common materials used in filter press cloths:

-

Cotton: Cotton is a popular choice for filter press cloths due to its high strength, durability, and resistance to chemicals.

-

Polyester: Polyester is a synthetic material that is known for its resistance to heat, chemicals, and abrasion.

-

Stainless Steel Fiber: Stainless steel fiber is a high-quality material that is known for its corrosion resistance, strength, and durability.

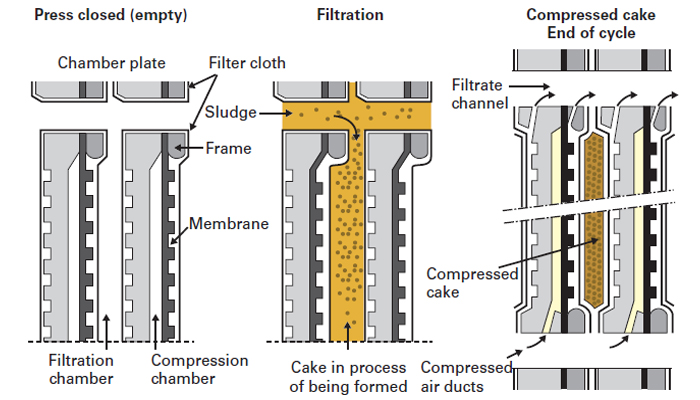

Evaluate the Weight

The weight of the filter press cloths is another important factor to consider. The weight of the cloths will affect the filtration process, and a heavier cloth may be more effective in certain applications. Here are some common weight ranges for filter press cloths:

-

Lightweight: 100-200 gsm

-

Medium weight: 200-400 gsm

-

Heavyweight: 400-600 gsm

Assess the Thread Count

The thread count of the filter press cloths is also an important factor to consider. The thread count refers to the number of threads per square inch of fabric. Here are some common thread counts for filter press cloths:

-

Low thread count: 100-150 threads per square inch

-

Medium thread count: 150-200 threads per square inch

-

High thread count: 200-250 threads per square inch

Consider the Finish

The finish of the filter press cloths is another important factor to consider. Different finishes can affect the performance of the clothes in different applications. Here are some common finishes for filter press cloths:

-

Smooth finish: A smooth finish is ideal for applications where the clothes will be subjected to high pressure and temperature.

-

Textured finish: A textured finish is ideal for applications where the clothes will be subjected to high abrasion and wear.

Evaluate the Price

The price of the filter press cloths is another important factor to consider. Different materials and finishes can affect the price of the clothes. Here are some tips to help you evaluate the price of the clothes:

-

Compare Prices from different suppliers: Comparing prices from different suppliers can help you find the best deal.

-

Consider the cost per unit: Calculate the cost per unit to determine the most cost-effective option.

Conclusion:

Choosing the proper filter press cloths for your industrial needs can be a challenging task, but with the right information, it can be a breeze. By considering the material, weight, thread count, finish, and price.

You can find the best clothes for your specific needs. Remember to evaluate your options carefully and choose the clothes that offer the best balance of quality and cost.

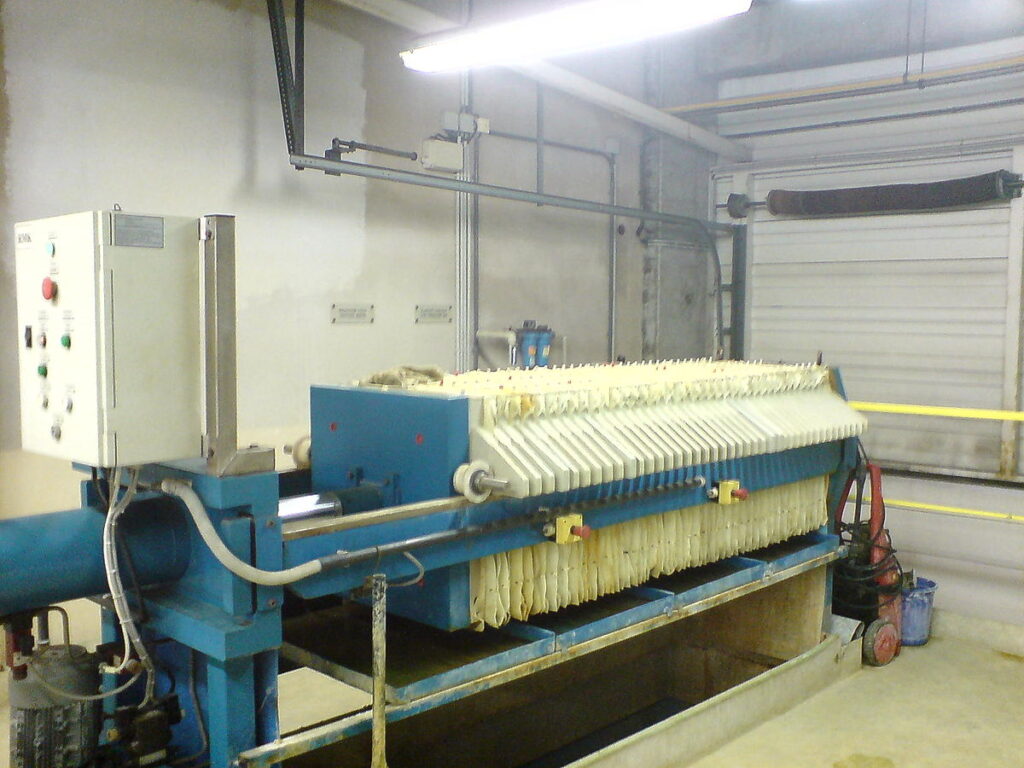

Hydraulic Filter Press: Working Principle and Advantages

This article provides an overview of the hydraulic filter press’s operation and benefits in many sectors. It also goes over the advantages of employing a hydraulic filter press and how it may boost the efficiency and efficacy of filtration procedures.

Hydraulic Filter Press Operation

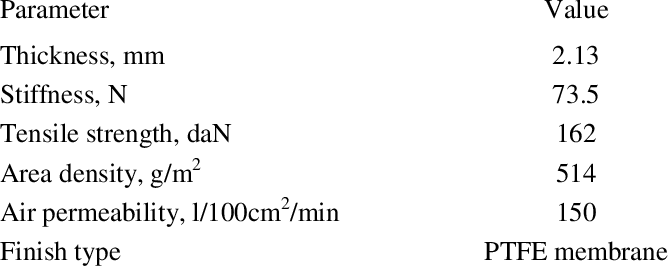

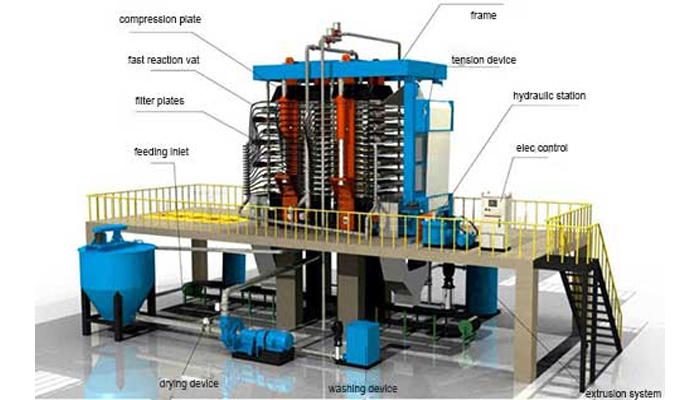

A hydraulic filter press is a device that separates particles from liquids by using hydraulic pressure. The filter pack is made up of a succession of plates and frames that are stacked together.

The plates have a series of pores that allow liquid to pass through while inhibiting solids. The filter pack is subjected to hydraulic pressure, which drives the liquid to pass through the plates while leaving the particulates behind.

Hydraulic Filter Press Benefits

There are various advantages to using a hydraulic filter press over traditional filtration methods. One of its primary benefits is its capacity to handle high-pressure and high-flow rate applications.

The hydraulic filter press can handle pressures up to 1000 psi and flow rates up to 1000 gpm, making it excellent for chemical, petrochemical, and oil refining applications.

The hydraulic filter press also can remove a wide spectrum of pollutants. The device can eliminate contaminants as small as 0.01 microns and as large as 100 microns, making it appropriate for a wide range of applications.

Furthermore, the hydraulic filter press is simple to operate and maintain because it requires little human intervention and is readily cleaned and serviced.

Hydraulic Filter Press Applications

The hydraulic filter press has numerous applications in a variety of sectors, including:

Chemical processing: The hydraulic filter press is used to remove impurities such as sulfur, carbon, and other pollutants from chemicals.

Petrochemical processing: The device is used to remove impurities such as water, salt, and other pollutants from crude oil.

Oil refining: The hydraulic filter press is used in oil refining to remove impurities such as water, carbon, and other pollutants from the oil.

Food and beverage processing: The device is used to eliminate impurities such as yeast, bacteria, and other pollutants from food and beverages.

Conclusion:

Finally, the hydraulic filter press is a versatile instrument that provides numerous advantages in a variety of sectors. It is an excellent choice for filtration processes due to its capacity to handle high-pressure and high-flow rate applications, remove a wide range of pollutants, and ease of operation and maintenance.

Industries can increase the efficiency and efficacy of their filtration operations by knowing the working principle and benefits of the hydraulic filter press, resulting in higher quality products and lower costs.

How do excavator track link contribute to the overall smoothness of movement and operational efficiency of construction equipment?

Excavator track links play a crucial role in contributing to the overall smoothness of movement and operational efficiency of construction equipment in several ways:

- Reduced Vibrations: Well-designed track links with optimized geometry, alignment, and proper tension contribute to minimizing vibrations during operation. Reduced vibrations improve operator comfort, reduce fatigue, and enhance the equipment’s stability.

- Improved Traction and Maneuverability: Properly functioning track links ensure consistent contact between the track shoes and the ground, optimizing traction. This improved traction facilitates better maneuverability, allowing the equipment to navigate various terrains more efficiently.

- Enhanced Stability: Track links help distribute the machine’s weight evenly across the tracks and undercarriage. This even weight distribution contributes to the equipment’s stability, especially when working on uneven or challenging terrains, reducing the risk of tipping or loss of control.

- Smooth Tracking and Alignment: Well-maintained and aligned track links ensure smooth tracking of the undercarriage components. Proper alignment reduces uneven wear on track components, enhancing overall efficiency and longevity.

- Reduced Resistance and Friction: Properly lubricated and maintained track links minimize resistance and friction during movement. Reduced friction results in smoother operation, improving fuel efficiency and reducing wear on undercarriage components.

- Optimized Performance: When track links are in optimal condition, the equipment’s overall performance improves. The excavator can achieve smoother transitions between movements, such as turning, traveling, and lifting, leading to increased operational efficiency.

- Operator Comfort: Smooth movement due to well-maintained track links enhances operator comfort. This improved comfort level allows operators to work more effectively and with greater precision, contributing to overall operational efficiency.

- Reduced Downtime: Properly functioning track links minimize the risk of failures or malfunctions, reducing unplanned downtime. This factor contributes significantly to the equipment’s overall operational efficiency and productivity.

In summary, excavator track links play a vital role in ensuring smooth movement, stability, and operational efficiency of construction equipment. Regular maintenance, proper alignment, adequate lubrication, excavator track link and choosing the right track link designs for specific applications are crucial for maximizing performance and minimizing disruptions during operation.

What are the primary materials used in manufacturing excavator track link, and how do they influence performance?

Excavator track links are typically manufactured using high-strength alloy steels or specialized alloys to meet the demands of heavy-duty construction applications. The primary materials used in their manufacturing include:

- Carbon and Alloy Steels: These steels offer a balance of strength, toughness, and wear resistance. They are commonly used in track link components to withstand the high stresses and abrasion encountered in construction environments.

- Boron Steel: Boron-added steels provide exceptional hardness and wear resistance. They are often used in high-wear areas of track links to enhance durability and longevity.

- Heat-Treated Steel Alloys: Alloy steels subjected to heat treatment processes like quenching and tempering offer improved mechanical properties, including increased strength and hardness. These materials are utilized in critical sections of track links to resist wear and deformation.

- Specialized Alloys and Composites: Advanced alloys or composite materials, sometimes with additional elements like chromium, manganese, or nickel, are used in track link components to achieve superior wear resistance, toughness, and fatigue strength.

The choice of materials significantly influences the performance of excavator track links:

- Wear Resistance: Materials with high hardness and wear resistance endure the abrasive forces encountered in construction environments, prolonging the track link’s lifespan and reducing the frequency of replacements.

- Strength and Toughness: High-strength materials maintain structural integrity under heavy loads, ensuring the track links can withstand the stresses of excavation, loading, and maneuvering without deformation or failure.

- Fatigue Resistance: Resilient materials with good fatigue resistance reduce the risk of cracking or failure, especially in sections subjected to repeated stress and cyclic loading.

- Corrosion Resistance: Some alloys are chosen for their corrosion-resistant properties, which are beneficial in environments where exposure to moisture, chemicals, or corrosive substances is prevalent.

- Weight Considerations: Materials that offer strength without excessive weight contribute to the overall weight efficiency of the equipment, impacting fuel consumption and maneuverability.

- Manufacturability: Materials chosen should be suitable for the manufacturing processes involved, such as forging, casting, or machining, ensuring the production of precise and durable track link components.

Overall, the selection of materials in excavator track links aims to achieve a balance between strength, wear resistance, toughness, and other specific performance characteristics to withstand the demanding conditions of construction and excavation activities.

Are there different types of track link designed for specific terrains or working conditions?

Can the design of track link impact fuel efficiency or the overall operating costs of heavy machinery?

Yes, the design of track links can significantly impact fuel efficiency and the overall operating costs of heavy machinery. Here’s how:

- Rolling Resistance: The design of track links influences rolling resistance, which refers to the force required to move the tracks. Reduced rolling resistance, achieved through optimized track link design, minimizes the energy needed to propel the machinery, improving fuel efficiency.

- Track Tension and Alignment: Properly designed track links contribute to maintaining appropriate track tension and alignment. Misaligned or excessively tensioned tracks can increase resistance, track link leading to higher fuel consumption and accelerated wear on undercarriage components.

- Wear and Maintenance: Certain track link designs offer improved durability and reduced wear on components. Durable track links require less frequent replacement or maintenance, reducing downtime and overall operating costs.

- Lubrication and Friction: Some track link designs incorporate better lubrication systems or materials that reduce friction between moving components. This reduces energy losses due to friction, contributing to improved fuel efficiency.

- Terrain Adaptability: Track links designed for specific terrains or conditions, such as low-ground-pressure or specialized links for soft terrain, enable the machinery to operate more efficiently in diverse environments. Efficient operation in different terrains can impact fuel usage and operating costs.

- Longevity and Lifecycle Costs: Track links with superior durability and longer lifespan reduce the frequency of replacements. Longer-lasting components lower the total cost of ownership by decreasing the need for frequent part replacements and associated maintenance expenses.

- Weight Optimization: Innovative track link designs aim to optimize weight without compromising strength. Reduced weight in track links contributes to lower overall machine weight, potentially improving fuel efficiency.

- Operational Efficiency: Well-designed track links ensure smooth operation and reduced resistance during movement. This operational efficiency minimizes strain on the engine, leading to potential fuel savings and reduced wear on associated parts.

In summary, track link design significantly impacts fuel efficiency and operating costs by influencing rolling resistance, wear rates, maintenance intervals, terrain adaptability, and overall operational efficiency. Choosing track links optimized for specific applications and operational conditions can positively impact fuel consumption and reduce the total cost of owning and operating heavy machinery.

Coconut Oil Filter Press: A Comprehensive Guide

Coconut oil filter press is a machine used to extract coconut oil from coconut milk. TIn this article, we will provide a comprehensive guide to coconut oil filter press, including its types, uses, and benefits.

Types of Coconut Oil Filter Press

There are several types of coconut oil filter press available in the market, each with its unique features and benefits. Some of the most common types include:

Plate and Frame Filter Press: This is the most common type of coconut oil filter press. It consists of a series of plates and frames that are stacked together to form a filter. The coconut milk is poured into the top plate, and the oil is collected in the bottom plate.

Screw Press: This type of filter press uses a screw mechanism to press the coconut milk through a filter. It is commonly used in large-scale coconut oil production.

Belt Press: This type of filter press uses a belt to press the coconut milk through a filter. It is a continuous process, and the belt can be easily replaced when it gets worn out.

Uses of Coconut Oil Filter Press

Coconut oil filter press has several uses in various industries, including:

Food and Beverage: Coconut oil is a popular ingredient in many food and beverage products, such as baked goods, smoothies, and cooking oils.

Cosmetics: Coconut oil is used in many cosmetic products, such as skin creams, hair care products, and soaps.

Pharmaceuticals: Coconut oil is used in some pharmaceutical products, such as capsules and tablets.

Industrial: Coconut oil is used in various industrial applications, such as in the production of biofuels, lubricants, and other chemicals.

Benefits of Coconut Oil Filter Press

The coconut oil filter press offers several benefits, including:

High-quality oil: The filter press helps to extract high-quality coconut oil that is free from impurities and contaminants.

Increased yield: The filter press can extract more oil from coconut milk than traditional methods, resulting in increased yield.

Cost-effective: The filter press is a cost-effective way to extract coconut oil, as it requires less labor and energy than traditional methods.

Easy to use: The filter press is easy to use and maintain, and it can be operated by anyone with basic training.

H3: Examples of Coconut Oil Filter Press

Several examples of coconut oil filter press include:

The Oilgae 1000: This is a plate and frame filter press that is designed for small-scale coconut oil production. It can extract up to 1000 liters of oil per day.

The Screw Press 5000: This is a screw press filter that is designed for large-scale coconut oil production. It can extract up to 5000 liters of oil per day.

The Belt Press 10000: This is a belt press filter that is designed for large-scale coconut oil production. It can extract up to 10000 liters of oil per day.

Conclusion

In conclusion, a coconut oil filter press is a machine that is used to extract coconut oil from coconut milk. It offers several benefits, including high-quality oil, increased yield, cost-effectiveness, and ease of use.

There are several types of coconut oil filter press available, including plate and frame, screw press, and belt press. The filter press is widely used in various industries, including food and beverage, cosmetics, pharmaceuticals, and industrial applications.

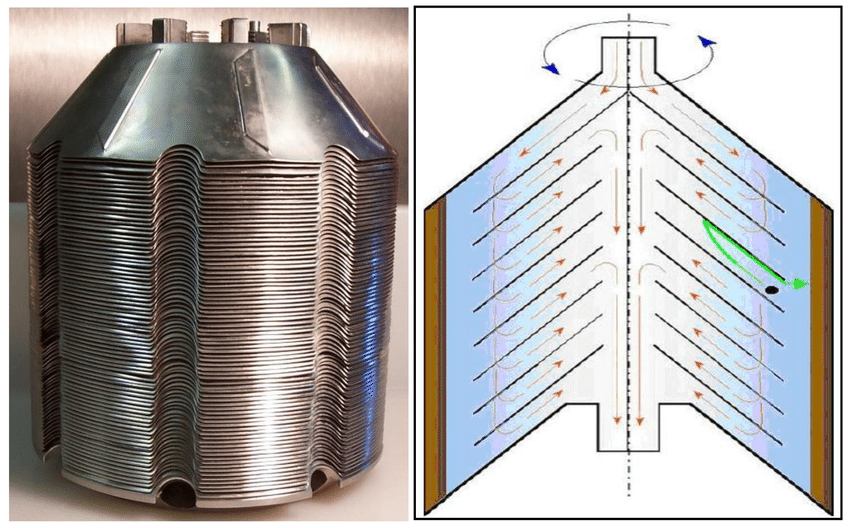

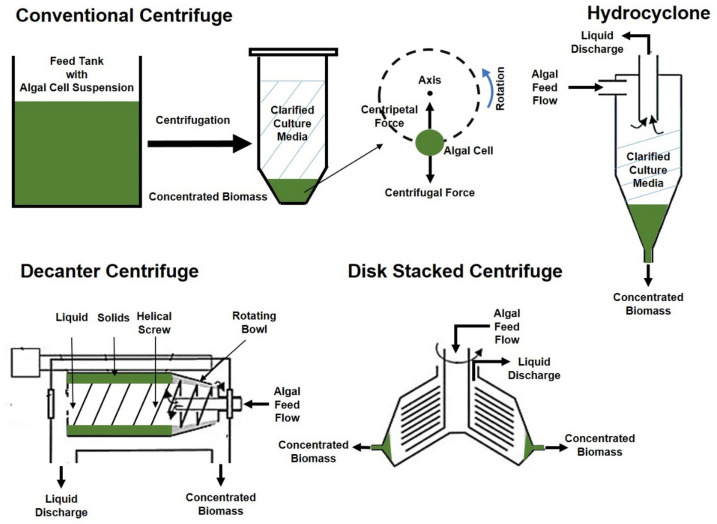

Disc Stack Centrifuge: A Revolutionary Separation Technology

The disc stack centrifuge is a cutting-edge separation technology that has gained widespread recognition in various industries. This revolutionary equipment has the potential to replace traditional separation methods.

What is a Disc Stack Centrifuge?

A disc stack centrifuge is a type of centrifuge that uses a stack of discs to separate particles or liquids of different densities or sizes. The discs are arranged in a vertical position and rotated at high speeds.

Creating a centrifugal force that separates the particles or liquids. The discs are designed with different hole sizes and shapes to accommodate various separation requirements.

Advantages of Disc Stack Centrifuges

Disc stack centrifuges offer several advantages over traditional separation methods, including:

-

Higher separation efficiency: Disc stack centrifuges can achieve higher separation efficiencies due to the unique design of the discs, which allows for better particle separation.

-

Cost-effectiveness: Disc stack centrifuges are more cost-effective than traditional methods, as they require less energy and maintenance.

-

Versatility: Disc stack centrifuges can be used for a wide range of applications, including liquid-liquid separation, solid-liquid separation, and particle separation.

Applications of Disc Stack Centrifuges

Disc stack centrifuges have numerous applications across various industries, including:

-

Chemical engineering: Disc stack centrifuges are used to separate chemicals and other particles in the chemical engineering industry.

-

Food and beverage: Disc stack centrifuges are used to separate liquids and particles in the food and beverage industry, such as in the production of fruit juices and dairy products.

-

Pharmaceuticals: Disc stack centrifuges are used to separate particles and liquids in the pharmaceutical industry, ensuring high-quality products.

-

Biotechnology: Disc stack centrifuges are used to separate biological particles and liquids in the biotechnology industry.

Examples of Disc Stack Centrifuge Applications

Some specific examples of disc stack centrifuge applications include:

-

Separating coffee beans from coffee grounds

-

Separating cornstarch from water

-

Separating blood cells from plasma

-

Separating bacteria from water

How to Choose the Right Disc Stack Centrifuge

Choosing the right disc stack centrifuge for your separation needs can be a challenge. Here are some factors to consider:

-

Capacity: Determine the capacity of the centrifuge you need, based on the volume of particles or liquids you need to separate.

- Disc size

and shape: Choose the appropriate disc size and shape for your separation requirements.

-

Rotational speed: Determine the rotational speed required for your separation needs.

-

Material: Choose a centrifuge made from materials that are compatible with your separation requirements, such as stainless steel or plastic.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting are essential to ensure your disc stack centrifuge operates efficiently and effectively. Here are some tips:

-

Regular cleaning and maintenance: Clean your centrifuge regularly and perform routine maintenance tasks to prevent wear and tear.

-

Troubleshooting guide: Keep a troubleshooting guide handy to help you identify and resolve common issues.

-

Professional assistance: Consult a professional if you encounter complex issues that you cannot resolve on your own.

Conclusion

Disc stack centrifuges are a revolutionary separation technology that offers enhanced efficiency, cost-effectiveness, and versatility. With their wide range of applications across various industries, disc stack centrifuges are an essential tool for many businesses.

By understanding the features, benefits, and applications of disc stack centrifuges, you can make an informed decision when choosing a centrifuge for your separation needs.

Composition of adult diaper production line

Adult diaper production line is a kind of automatic production equipment for producing adult diapers. It consists of a series of machines, including mixers, bins, slitting machines, diaper machines, backing machines, embossing machines, winding machines and so on. These machines are controlled by an automated control system to realize the process of continuous production of adult diaper machine.

I. Mixer

Mixer is the first process in the production line of adult diapers, which is used to mix all kinds of raw materials, such as crystal cotton, wood pulp fiber, absorbent paper, SAP, PE film and so on. The mixer rotates to ensure that the raw materials are fully mixed and reach a certain proportion.

Second, the material box

The material box is to send the mixed raw materials into the following diaper machine through the pipe, to ensure the supply of raw materials is sufficient, and will not be cut off during the production process, but also to control the quality of the product.

Third, cutting machine

Slitting machine is one of the core equipments in the adult diaper production line, which cuts the molded diaper rolls into strips of different sizes in order to meet the needs of people with different body sizes. The slitting machine is pressure-driven and divides the paper into the required length and width by means of pressing.

Fourth, diaper machine

The diaper machine is another core equipment in the adult diaper production line, which cures the mixed raw materials into the required product form, i.e. molded diapers. The diaper machine contains several processes, such as water spraying, drying, pressing and so on. In the production process, the diaper machine through automated control systems to ensure product quality and production efficiency,sanitary napkin machine for sale

V. Back film machine

Back film machine is one of the auxiliary equipment in the adult diaper production line, which is mainly used to laminate the back of the diaper to increase the waterproof performance of the product. Back film machine is using colloidal technology to cover the PE film on the back of the diaper to make it waterproof.

Sixth, embossing machine

Embossing machine is one of the auxiliary equipments in the adult diaper production line, it is mainly used for printing, silk pressing and other processing of the product to increase the beauty and comfort of the product.

Seven, winding machine

Winding machine is a link behind the adult diaper production line, it will produce good adult diapers continuously rolled into a certain length of the volume, so that it is convenient for packaging and storage. Through the automatic control system, the winding machine ensures the consistency of the product specifications and improves the production efficiency at the same time.

How to Select Suitable Filter Cloth Specification for Clear Filtration

Many industrial processes rely on filter cloth specifications, such as those for filtering, separation, and purification. Choosing the right filter cloth specification is essential for effective filtering, and we’ll go over all the factors to consider in this post to help you make that decision.

A First Look at Filter Cloth Specifications

An essential part of many industrial filtering systems, filter cloth is defined by a set of specifications that outline its qualities and characteristics.

The efficiency and effectiveness of filter cloth, a porous material used to remove solid particles from liquids or gases, are greatly affected by its specification.

Filter Cloth Models

To cater to various business needs, filter cloth specifications come in a variety of styles. These are a few examples of the most typical filter cloth specifications:

-

Rating in microns: This indicates the size, in microns, of the filter cloth’s pores. More fine filtering is possible with smaller pores and a higher micron rating, which is used to determine the size of particles that can pass through the filter cloth.

-

Fabric: Filter cloth is available in several different materials, including cotton, nylon, and polyester. Every material has its own set of benefits and drawbacks; picking one over another is a matter of determining the precise field of use.

-

Filter cloth is named for the pattern created by weaving together the yarns. The porosity, strength, and longevity of the filter fabric are all influenced by the weave.

-

Another important factor that determines the filter cloth’s efficacy and longevity is its thickness. Although thinner filter cloths may be more suited for low-pressure applications, thicker cloths can endure higher pressures and offer superior filtration.

Factors to Consider When Choosing the Specification of Filter Cloth

Several things should be thought about while choosing the filter fabric specification for clean filtering. Among these factors are:

Region of use: The filter cloth specification needed is determined by the region of use. To maintain product quality and purity, certain industries, such as those dealing with food and drink, may need filter cloths with higher micron ratings.

Particulate matter: The filter cloth specification is influenced by the particle size. For instance, a filter cloth with a higher micron rating might be necessary to capture extremely tiny particles.

In addition to the filter cloth’s dimensions, the flow rate of the filtered gas or liquid is another important consideration. To make sure the filter cloth can handle the pressure, a thicker cloth might be needed for a higher flow rate.

Another factor that impacts filter cloth specifications is the pressure drop over it. If the pressure drop is high, then the filter fabric needs to be thicker to handle it.

You should also think about how much the filter cloth standard will cost. The available budget will determine the specification of the filter cloth, as the cost of different materials and weaves can vary.

Pros of Using the Right Filter Cloth Specification

Several advantages can be achieved with the right filter cloth specification, such as:

-

Gaining the target degree of purity is easier with improved filtration efficiency, which can be accomplished with the right filter cloth specification.

-

Reducing the requirement for maintenance and downtime, increased productivity can be achieved with proper filter cloth specification.

-

Expense savings: By reducing waste and enhancing yields, the suitable filter cloth specification can help to save costs.

-

Higher-quality result: Accurate filter cloth specifications are a must for many industrial uses because they guarantee a high-quality result.

Finally, many industrial processes rely on filter cloth specifications, such as those for filtration, separation, and purification. Industrial processes can be made more efficient and of higher quality when operators have a firm grasp of the many filter cloth specifications and the many uses for each.

Enhanced filtration efficiency, higher productivity, reduced costs, and better product quality are just a few of the many advantages that can result from using filter cloths that are properly specified.

What is a Hydraulic Filter Press and How Does it Work?

A hydraulic filter press is a type of filter press that uses hydraulic pressure to separate solids from liquids. It is widely used in various industries such as chemical, petrochemical, pharmaceutical, and food and beverage.

How a Hydraulic Filter Press Works

A hydraulic filter press consists of a series of plates and frames that are alternately pressed together to form a chamber. The liquid to be filtered is pumped into the chamber, and the solids are trapped in the filter press.

The hydraulic pressure is then applied to the plates, which forces the liquid through the filter press, leaving the solids behind. The filtered liquid is then collected, and the solids are removed from the filter press.

Advantages of Hydraulic Filter Press

The hydraulic filter press has several advantages over other types of filter presses. One of the main advantages is its high filtration efficiency.

The hydraulic pressure ensures that the liquid is forced through the filter press, leaving no room for impurities to pass through. This results in a higher quality of filtration, making it ideal for applications where high purity is required.

Another advantage of the hydraulic filter press is its versatility. It can be used to filter a wide range of liquids, from water to oil, and from chemicals to food and beverage. It is also easy to operate and maintain, making it a cost-effective solution for many industries.

Applications of Hydraulic Filter Press

The hydraulic filter press has a wide range of applications in various industries. In the chemical industry, it is used to filter chemicals and remove impurities. In the petrochemical industry, it is used to filter oil and remove impurities.

In the pharmaceutical industry, it is used to filter drugs and remove impurities. In the food and beverage industry, it is used to filter liquids and remove impurities, ensuring the quality of the final product.

Benefits of Hydraulic Filter Press

The hydraulic filter press offers several benefits, including:

-

High filtration efficiency

-

Versatility in application

-

Easy to operate and maintain

-

Cost-effective solution

-

Ideal for applications where high purity is required