20 Foot 2 Inch Steel Pipe Applications and Benefits

Steel pipes are widely used in various industries for their durability, versatility, and cost-effectiveness. Among the different sizes and thicknesses of steel pipes, 20 foot 2 inch steel pipe stands out for its unique applications and benefits.

In this article, we will explore the uses and advantages of 20 foot 2 inch steel pipe, and why it is an excellent choice for certain industries and projects.

Applications of 20 Foot 2 Inch Steel Pipe

Oil and Gas Industry: 20 foot 2 inch steel pipe is commonly used in the oil and gas industry for transporting crude oil, natural gas, and other petroleum products. Its large diameter and length make it ideal for long-distance pipelines, allowing for efficient and cost-effective transportation.

Water Supply Systems: 20 foot 2 inch steel pipe is also used in water supply systems for municipalities and industrial facilities. Its large diameter allows for high water flow rates, making it suitable for supplying water to large populations and industrial processes.

Structural Support: 20 foot 2 inch steel pipe can be used for structural support in large buildings and bridges. Its high strength-to-weight ratio and resistance to corrosion make it an ideal material for supporting heavy loads and withstanding harsh environmental conditions.

Agricultural Irrigation: 20 foot 2 inch steel pipe is used in agricultural irrigation systems for transporting water to fields and crops. Its large diameter allows for efficient water distribution, making it an essential tool for farmers and agricultural producers.

Benefits of 20 Foot 2 Inch Steel Pipe

Durability: 20 foot 2 inch steel pipe is made from high-quality steel that is resistant to corrosion and wear, ensuring a long lifespan and reducing maintenance costs.

Cost-Effectiveness: 20 foot 2 inch steel pipe is a cost-effective solution for various industries, as it can be easily installed and maintained, reducing labor and material costs.

Versatility: 20 foot 2 inch steel pipe can be used in a variety of applications, from oil and gas transportation to water supply systems and structural support.

High Strength-to-Weight Ratio: 20 foot 2 inch steel pipe has a high strength-to-weight ratio, making it strong and lightweight, allowing for easy transportation and installation.

Conclusion

In conclusion, 20 foot 2 inch steel pipe is a versatile and cost-effective solution for various industries, offering numerous benefits and applications. Its durability, high strength-to-weight ratio, and corrosion resistance make it an ideal material for transporting fluids, supporting heavy loads, and withstanding harsh environmental conditions.

Whether you are in the oil and gas industry, water supply systems, structural support, or agricultural irrigation, 20 foot 2 inch steel pipe is an excellent choice for your projects.

Screw Press Dewatering Machine Price

The food industry is constantly evolving, and one of the latest advancements is the use of screw press dewatering machines. In this article, we will explore the benefits of using screw press dewatering machines and how they can improve the quality of food products.

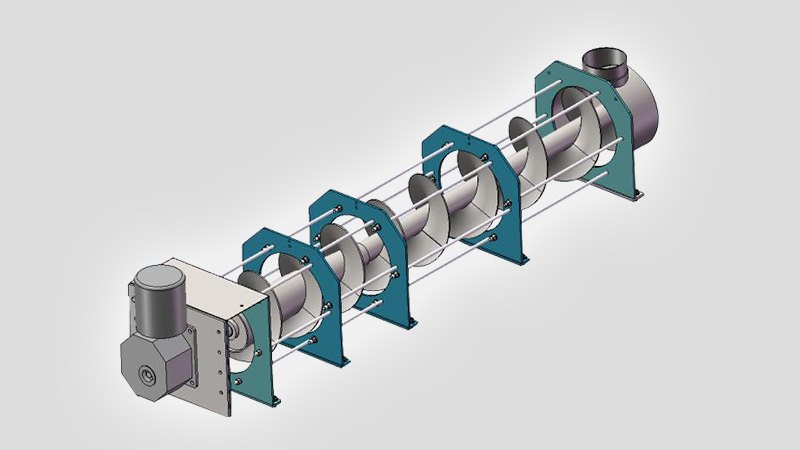

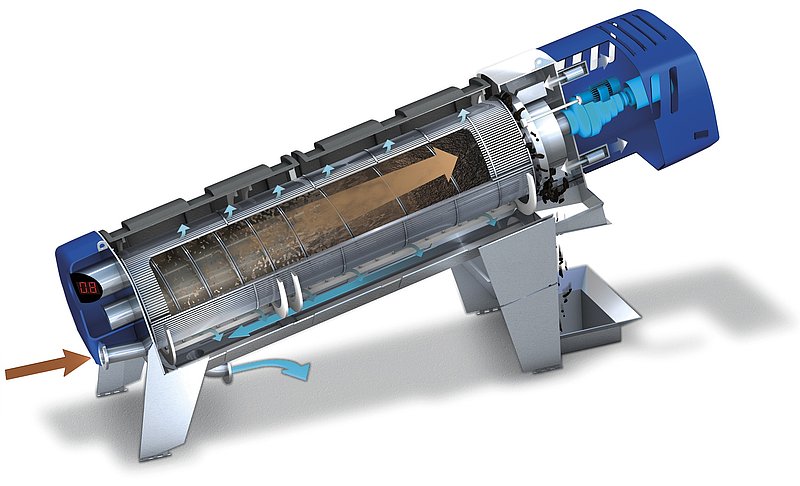

What is a Screw Press Dewatering Machine?

A screw press dewatering machine is a piece of equipment that is specifically designed to remove excess moisture from food products. It works by using a rotating screw to compress the food, causing the moisture to be released and removed from the product. This results in a drier, more stable food product that is easier to store and transport.

Benefits of Using a Screw Press Dewatering Machine

There are several benefits to using a screw press dewatering machine in the food industry. Some of the most significant advantages include:

Improved Food Safety

One of the most important benefits of using a screw press dewatering machine is improved food safety. By removing excess moisture from food products, these machines help to reduce the risk of contamination and spoilage. This is especially important for food products that are sensitive to moisture, such as meat and dairy products.

Increased Storage Life

Another benefit of using a screw press dewatering machine is increased storage life. By removing excess moisture from food products, these machines help to prolong the shelf life of the product. This is especially important for food products that are perishable, such as fruit and vegetables.

Improved Texture

Using a screw press dewatering machine can also improve the texture of food products. By removing excess moisture, these machines help to create a crispier, more stable texture that is easier to chew and digest. This is especially important for food products that are meant to be consumed in a specific way, such as crackers and bread.

Cost Savings

Finally, using a screw press dewatering machine can also save money in the long run. By removing excess moisture from food products, these machines help to reduce the amount of waste that is generated. This can help to reduce costs associated with packaging and transportation.

Conclusion

In conclusion, screw press dewatering machines are a valuable tool in the food industry. By removing excess moisture from food products, these machines help to improve food safety, increase storage life, improve texture, and save money. If you are looking for a way to improve the quality of your food products, consider investing in a screw press dewatering machine today.

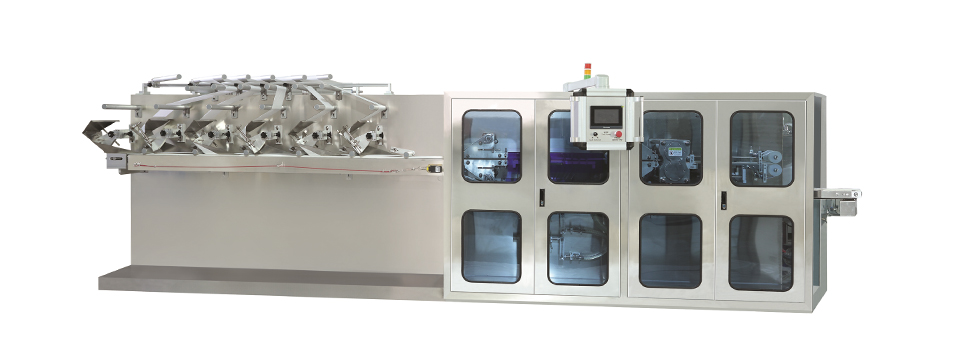

How does a wet towel machine manage the dispensing of a specific number of towels?

The management of dispensing a specific number of towels in a wet towel machine typically involves the integration of various technologies and features to ensure accurate and controlled towel distribution.

Here are common methods used to manage the dispensing of a specific number of towels:

- Electronic Counting System: Many wet towel machines utilize an electronic counting system to keep track of the number of towels dispensed. This system can use sensors or other detection mechanisms to register each dispensed towel and update the count accordingly.

- Programmable Settings: Users can often program the wet towel machine to dispense a predetermined number of towels per cycle. This can be done through the machine’s control panel or interface, allowing users to customize the dispensing quantity based on their preferences or specific requirements.

- Microcontroller or Processor: Wet towel machines may incorporate a microcontroller or processor that manages the overall operation of the machine. This component can play a crucial role in accurately controlling the dispensing process, including ensuring the correct number of towels is dispensed.

- User Input and Selection: Some machines provide users with the option to manually input the desired number of towels before starting the dispensing process. This user input is then used by the machine’s internal system to control the dispensing mechanism accordingly.

- Batch Dispensing: In addition to single towel dispensing, certain wet towel machines offer batch dispensing features. Users can specify the number of towels they need, and the machine dispenses them in batches, wet wipe sticker making it convenient for users who require multiple towels at once.

- Display and Feedback: Machines often have a display panel or indicator lights that show the remaining number of towels available or the progress of the dispensing cycle. This provides users with real-time feedback on the status of towel dispensing.

- Automatic Shut-Off: Once the preset number of towels has been dispensed, some machines have an automatic shut-off feature to stop the dispensing process. This helps prevent overuse of towels and ensures that the specified quantity is maintained.

- Smart Features: In advanced wet towel machines, smart features may be integrated, allowing users to control and monitor towel dispensing remotely through mobile apps or other smart interfaces. This can include setting specific counts and receiving notifications.

It’s important for users to refer to the user manual or guidelines provided by the manufacturer to understand the specific features and functionalities related to towel dispensing on a particular wet towel machine. This ensures proper usage and maximizes the effectiveness of the towel dispensing system.

How does a wet towel machine address issues of towel jamming or malfunction?

The specific mechanisms to address towel jamming or malfunctions in wet towel machines may vary depending on the design and features of the machine.

However, here are some common methods and features that are often employed to address such issues:

- Sensors and Detection Systems: Many wet towel machines are equipped with sensors that can detect abnormalities in the towel dispensing process. If the sensors identify a jam or malfunction, the machine may automatically pause or initiate corrective actions.

- Anti-Jamming Mechanisms: Some machines incorporate anti-jamming features in their dispensing mechanisms. This can include mechanisms that prevent multiple towels from being dispensed simultaneously or features that detect irregularities in towel movement.

- Automated Resetting: In the event of a jam or malfunction, some wet towel machines have an automated resetting process. This may involve temporarily stopping the operation, clearing the jam, and then resuming normal functionality.

- User Alerts and Notifications: Machines may be programmed to display error messages or alerts on the control panel, indicating the nature of the issue. This helps users identify and address problems promptly.

- Manual Override: In cases where automated measures are not sufficient, users may have the option to manually override the machine. This could involve accessing a manual release mechanism or following specific steps outlined in the machine’s user manual.

- Regular Maintenance Requirements: To prevent potential issues, wet towel machine production line wet towel machines often come with recommended maintenance schedules. Regular cleaning, lubrication, and inspection can help minimize the likelihood of jams or malfunctions.

- Quality Construction: High-quality materials and construction can contribute to the overall reliability of the machine. Robust and durable components are less likely to malfunction or cause jams during regular operation.

- Customer Support and Service: Manufacturers may provide customer support services, including troubleshooting guides and assistance. In cases of persistent issues, users may be able to contact customer support for further guidance or arrange for professional servicing.

It’s important to note that the specific features and mechanisms to address towel jamming or malfunctions can vary between different models and brands of wet towel machines. Users should refer to the manufacturer’s instructions and guidelines for proper usage, maintenance, and troubleshooting.

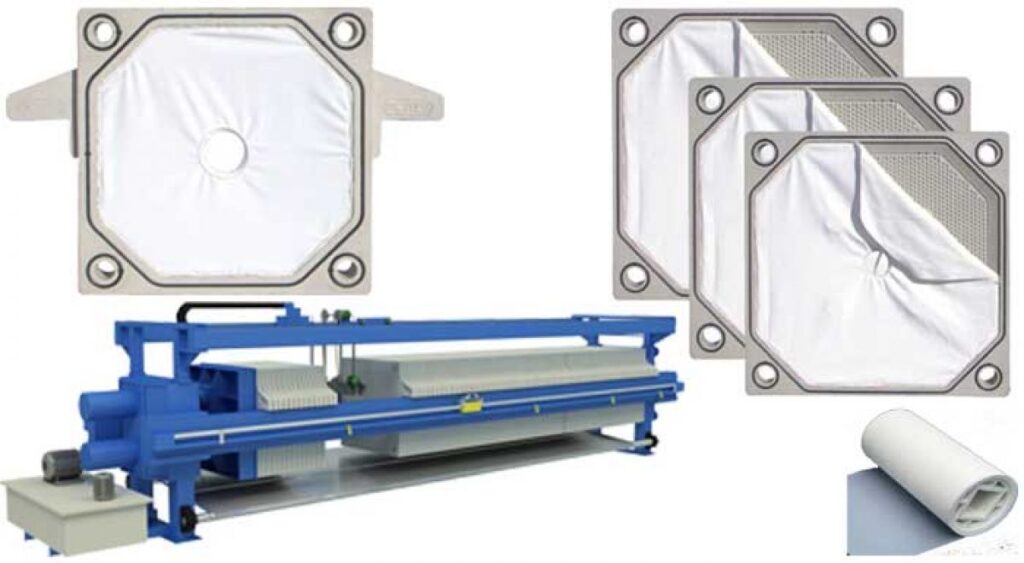

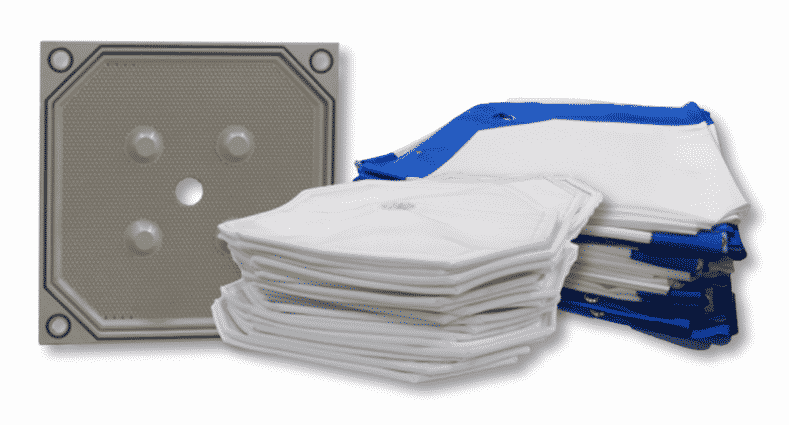

Different Types of Filter Press

Filter presses are an essential tool in various industries, including chemical processing, food and beverage, pharmaceuticals, and wastewater treatment. In this article, we will explore the different types of filter presses, their features, and their applications.

Types of Filter Press

There are several types of filter presses, each with its unique characteristics and uses. The most common types of filter presses include:

Plate and Frame Filter Press: This is the most common type of filter press, consisting of a series of plates and frames that separate solids from liquids.

The plates are made of metal or polypropylene, and the frames are made of metal or plastic. This type of filter press is used in various industries, including chemical processing, food and beverage, and wastewater treatment.

Membrane Filter Press: This type of filter press uses a thin, flexible membrane instead of plates and frames. The membrane is made of polypropylene or polyester, and it is designed to filter out finer particles than plate and frame filter presses.

Membrane filter presses are commonly used in applications where high purity is required, such as in the production of pharmaceuticals.

Cartridge Filter Press: This type of filter press uses a cartridge-type filter element, which is made of pleated paper or synthetic material.

The cartridge is designed to filter out particles and impurities from the liquid, and it can be easily replaced when it becomes clogged. Cartridge filter presses are commonly used in applications where space is limited, such as in laboratories or pilot plants.

Candle Filter Press: This type of filter press uses a cylindrical filter element, which is made of pleated paper or synthetic material.

The candle filter press is designed to filter out particles and impurities from the liquid, and it can be used in various industries, including chemical processing, food and beverage, and wastewater treatment.

Automatic Filter Press: This type of filter press is equipped with automated controls and systems, which allow for continuous operation and minimal maintenance.

Automatic filter presses are commonly used in large-scale industrial applications where high productivity and low maintenance are required.

Applications of Filter Presses

Filter presses have a wide range of applications in various industries, including:

Chemical Processing: Filter presses are used to separate solids and liquids in chemical processing applications, such as in the production of chemicals, pharmaceuticals, and fuels.

Food and Beverage: Filter presses are used to filter out impurities and contaminants from food and beverage products, such as fruit juice, wine, and dairy products.

Pharmaceuticals: Filter presses are used to filter out impurities and contaminants from pharmaceutical products, such as medicines and vaccines.

Wastewater Treatment: Filter presses are used to separate solids and liquids in wastewater treatment applications, such as in the treatment of industrial wastewater and domestic wastewater.

Benefits of Filter Presses

Filter presses offer several benefits, including:

High Filtration Efficiency: Filter presses can filter out particles and impurities with high efficiency, resulting in a high-quality product.

Low Maintenance: Filter presses are designed to be easy to maintain, with few moving parts and a simple design.

Continuous Operation: Filter presses can operate continuously, allowing for high productivity and minimal downtime.

Versatility: Filter presses can be used in a wide range of applications, making them a versatile tool in various industries.

Conclusion

Filter presses are an essential tool in various industries, offering high filtration efficiency, low maintenance, continuous operation, and versatility. There are several types of filter presses, each with its unique characteristics and uses.

By understanding the different types of filter presses and their applications, industries can make informed decisions about which filter press is best for their needs.

Whether it’s a plate and frame filter press, membrane filter press, cartridge filter press, candle filter press, or automatic filter press, there is a filter press that can meet the specific requirements of any industry.

Filter Press Manufacturers in USA

If you’re looking for filter press manufacturers in the USA, you’ve come to the right place. In this article, we’ll provide you with a comprehensive guide to the top filter press manufacturers in the country, including their features, benefits, and applications.

Top Filter Press Manufacturers in the USA

When it comes to filter press manufacturers in the USA, several names stand out from the rest. Here are some of the top manufacturers to consider:

Filter Press Manufacturers, Inc. – With over 30 years of experience, Filter Press Manufacturers, Inc. is a leading provider of filter presses for various industries, including chemical, food, and pharmaceutical.

Evoqua Water Technologies – Evoqua Water Technologies is a global leader in water and wastewater treatment solutions, offering a range of filter presses for various applications.

Graver Technologies – Graver Technologies is a trusted name in the filter press industry, offering a wide range of filter presses for chemical, petrochemical, and refining applications.

Aqua-Chem, Inc. – Aqua-Chem, Inc. is a leading provider of water treatment solutions, including filter presses, for various industries, including municipal, industrial, and commercial.

US Filter Press – US Filter Press is a leading manufacturer of filter presses for various industries, including chemical, food, and pharmaceutical.

Features and Benefits of Filter Presses

Filter presses are designed to separate solids from liquids, and they offer several benefits, including:

High efficiency – Filter presses are highly efficient, with some models capable of filtering up to 99% of particles.

Cost-effective – Filter presses are cost-effective, as they reduce the need for chemicals and energy required for treatment.

Versatility – Filter presses can be used in various industries, including chemical, food, and pharmaceutical.

Easy maintenance – Filter presses are easy to maintain, with simple and quick-to-replace parts.

Applications of Filter Presses

Filter presses have a wide range of applications, including:

Chemical processing – Filter presses are used to separate solids and liquids in chemical processing, such as in the production of chemicals, pharmaceuticals, and fuels.

Food and beverage – Filter presses are used in the food and beverage industry to separate solids from liquids, such as in the production of fruit juice, wine, and dairy products.

Pharmaceuticals – Filter presses are used in the pharmaceutical industry to separate solids from liquids, such as in the production of medicines and vaccines.

Water treatment – Filter presses are used in water treatment plants to separate solids from liquids, such as in the removal of suspended solids, bacteria, and viruses.

Choosing the Right Filter Press Manufacturer

Choosing the right filter press manufacturer is essential to ensure that you get a high-quality product that meets your specific needs. Here are some factors to consider when choosing a filter press manufacturer:

Experience – Look for a manufacturer with a proven track record of producing high-quality filter presses.

Customization – Choose a manufacturer that offers customized solutions to meet your specific needs.

Cost – Consider the cost of the filter press, as well as the cost of maintenance and replacement parts.

Quality – Look for a manufacturer that uses high-quality materials and has a strong reputation for producing reliable products.

Conclusion

In conclusion, filter press manufacturers in the USA offer a wide range of products and services to various industries. When choosing a filter press manufacturer, consider factors such as experience, customization, cost, and quality.

By doing so, you’ll be able to find the right manufacturer to meet your specific needs and ensure that your filter press operates efficiently and effectively.

We hope this guide has provided you with valuable information on filter press manufacturers in the USA. If you have any questions or would like to learn more, please don’t hesitate to contact us.

How do environmental variables such as soil composition, climate, and topography impact the performance of round dripper drip tube systems?

Environmental variables significantly impact the performance of round dripper drip tube systems in agricultural settings:

- Soil Composition:

- Water Infiltration Rates: Different soil types affect water infiltration rates. Round dripper drip tubes might require adjustments in scheduling or emitter spacing to accommodate varying soil compositions.

- Clogging Risk: Soil composition influences the risk of emitter clogging. Soils with higher sediment content or organic matter may pose a greater risk, necessitating proper filtration and maintenance to prevent clogging.

- Climate:

- Temperature and Evaporation: Higher temperatures increase evaporation rates, impacting water efficiency. In hotter climates, round dripper systems might require adjustments in watering frequency or timing to account for increased water loss.

- Precipitation Patterns: Areas with inconsistent or heavy rainfall need drip systems with controllers or sensors to adapt irrigation schedules, avoiding overwatering during rainy periods.

- Topography:

- Slope and Elevation: Topography influences water distribution and pressure in the system. Sloped terrain may require tailored system designs to prevent runoff and ensure uniform water application. Elevation changes affect water pressure, necessitating adjustments to maintain consistent flow.

- Plant and Root Zones:

- Root Depth and Plant Water Uptake: The depth and density of plant root zones affect water requirements. Round dripper systems need to accommodate different plant water needs and ensure water reaches the appropriate root depths.

- Humidity and Wind:

- Evaporation and Drift: Higher humidity reduces evaporation rates, while windy conditions can cause water drift or evaporation. Adjustments in watering schedules or system design might be necessary to address these factors.

- Water Quality:

- Chemical Composition: Water quality impacts clogging risks due to mineral deposits or chemical reactions. Water with high mineral content may increase the potential for emitter clogging, necessitating adequate filtration systems.

- Water Availability: Environmental factors impacting water availability, round dripper drip tube such as drought or seasonal variations, require careful adjustment of irrigation schedules to optimize water use and support plant growth.

Understanding and adapting to these environmental variables are essential for optimizing the performance of round dripper drip tube systems. Adjustments in system design, irrigation schedules, maintenance practices, and technology implementation help mitigate the impacts of these environmental factors, ensuring efficient water delivery and supporting optimal crop growth in diverse conditions.

How does the use of round dripper drip tubes contribute to water conservation and efficient irrigation practices in agriculture?

Round dripper drip tubes contribute significantly to water conservation and efficient irrigation practices in agriculture through several mechanisms:

- Precise Water Application: Round dripper systems deliver water directly to the root zone of plants, minimizing water wastage. This precision ensures that water reaches where it’s needed most, reducing evaporation and runoff.

- Reduced Water Loss: By supplying water directly to the plant root zone, round dripper systems minimize surface evaporation compared to overhead irrigation methods. This reduces water loss to evaporation, especially in hot or arid climates.

- Minimized Soil Erosion: Controlled water delivery prevents soil erosion by avoiding excessive surface runoff. It maintains soil structure and integrity, reducing the loss of fertile topsoil due to water runoff.

- Optimized Water Use Efficiency: Round dripper systems enable efficient water use by delivering small, measured amounts of water precisely to each plant. This controlled application matches the plant’s water needs, minimizing excess water use.

- Fertigation Capability: Integration of fertilizers or nutrients into the irrigation water (fertigation) through round dripper systems enhances nutrient uptake by plants. This practice improves water and nutrient efficiency, promoting plant health and growth.

- Adaptability to Soil Variations: Round dripper systems can be tailored to different soil types and conditions, allowing adjustments in emitter spacing or flow rates to accommodate varying soil moisture levels and minimize water waste.

- Flexibility in Layout and Design: These systems offer flexibility in layout and design, allowing customization to match crop spacing, plant density, and field shapes. This adaptability maximizes water distribution efficiency.

- Environmental Sustainability: By conserving water resources and reducing runoff and leaching of fertilizers or chemicals, round dripper systems promote environmental sustainability in agriculture.

- Reduction in Weed Growth: Precise water application to the root zone reduces moisture availability in inter-row spaces, minimizing weed growth and competition for water resources.

- Enhanced Crop Health and Yield: Consistent and controlled water delivery through round dripper systems supports better crop health, leading to improved yields and quality of agricultural produce.

The use of round dripper drip tubes promotes water conservation, minimizes water waste, optimizes nutrient delivery, enhances crop health, and contributes to overall sustainability in agriculture by efficiently meeting the water needs of plants while minimizing environmental impact.

What maintenance practices are recommended for ensuring the longevity and optimal functionality of agriculture drip tape systems?

Maintaining agriculture drip tape systems is crucial for ensuring their longevity and optimal functionality. Here are recommended maintenance practices:

- Regular Inspection: Periodically inspect the entire drip tape system for leaks, clogs, or damage. Check connections, emitters, and tubing for any issues that might affect performance.

- Cleaning Filters: Clean or replace filters regularly to prevent clogging caused by debris or sediment. This ensures uninterrupted water flow and maintains system efficiency.

- Flushing the System: Flush the drip tape system periodically to remove any accumulated dirt, sediment, or mineral deposits. This helps prevent clogging and ensures even water distribution.

- Pressure Regulation: Monitor and maintain consistent pressure within the system using pressure regulators. Fluctuations in pressure can affect the performance of the drip tape, so ensuring stability is vital.

- Proper Storage: When not in use, store drip tapes properly in a clean and dry environment to prevent damage from UV exposure, pests, or physical deterioration.

- Adjustment and Repairs: Promptly repair or replace damaged or malfunctioning components, agriculture drip tape such as emitters or connectors. Adjust flow rates or replace worn-out parts to maintain optimal performance.

- Weed and Root Management: Regularly check for weed growth or roots that might infiltrate the drip tape system. Remove vegetation that can block emitters or cause damage.

- System Flushing Before Use: Before each irrigation season, flush the system to remove any residue, contaminants, or standing water that might have accumulated during the offseason.

- Protection from Physical Damage: Take precautions to protect the drip tape from physical damage caused by machinery, animals, or human interference.

- Professional Assessment: Periodically seek professional assessment or consultation to ensure the system is functioning optimally and to address any potential issues proactively.

By following these maintenance practices, farmers and growers can prolong the life of agriculture drip tape systems, ensure consistent and efficient water delivery, and maximize their effectiveness in supporting crop growth and health. Regular maintenance helps prevent issues, reduces downtime, and enhances the overall performance and longevity of the irrigation system.

How do environmental factors such as soil composition, climate, and topography impact the performance of agriculture drip tape?

Environmental factors such as soil composition, climate, and topography significantly influence the performance of agriculture drip tape systems in several ways:

- Soil Composition:

- Water Infiltration: Soil type affects water infiltration rates. Drip tape systems perform differently in sandy soils (rapid infiltration) compared to clay soils (slower infiltration), necessitating adjustments in irrigation scheduling.

- Clogging Risk: Soil composition can impact the risk of clogging. Soils with higher levels of sediment or organic matter might increase the likelihood of emitter clogging, requiring more frequent maintenance.

- Climate:

- Temperature: High temperatures can increase evaporation rates, affecting water application efficiency. Drip tape systems in hotter climates may need more frequent watering or adjustments in scheduling to compensate for increased water loss.

- Precipitation Patterns: Regions with erratic rainfall might require drip systems to be equipped with sensors or controllers to adapt irrigation schedules accordingly, avoiding overwatering during rainy periods.

- Topography:

- Slope and Elevation: Topography impacts water distribution and pressure within the system. Sloped terrains require careful design to prevent runoff and ensure even water application. Elevation changes affect water pressure, requiring adjustments to maintain uniform flow.

- Vegetation and Root Zones:

- Plant Water Uptake: The root zone depth and density of vegetation influence water requirements. Drip tape systems must cater to different plant water needs and ensure water reaches the appropriate root depths.

- Humidity and Wind:

- Evaporation and Drift: Higher humidity levels might reduce evaporation rates, while windy conditions can lead to water drift or evaporation. Adjustments in watering schedules or system design may be needed to account for these factors.

- Water Quality:

- Chemical Composition: Water quality impacts the potential for clogging due to mineral deposits or chemical reactions. Water with high mineral content may increase the risk of emitter clogging, necessitating appropriate filtration systems.

Understanding and adapting to these environmental factors are essential for optimizing the performance of agriculture drip tape systems. Adjustments in irrigation schedules, maintenance practices, system design, and technology implementation can mitigate the impacts of these environmental variables, ensuring efficient water delivery and supporting optimal crop growth in varying conditions.

Filter Press Manufacturers in USA

Filter press manufacturers in the United States play a vital role in the production of various products, including food, beverages, and pharmaceuticals.In this article, we will explore the top filter press manufacturers in the US, their products, and their services.

Top Filter Press Manufacturers in the USA

-

Jingjin manufacturer: Jingjin Manufacturer is a leading manufacturer of filter presses, valves, and other process control equipment. Their products are used in a wide range of industries, including food, beverage, and pharmaceuticals.

-

Waters Corporation: Waters Corporation is a global leader in the development and manufacture of laboratory equipment, including filter presses. Their products are used in research and development, quality control, and production processes.

-

Thermo Fisher Scientific: Thermo Fisher Scientific is a multinational corporation that provides a wide range of scientific instruments and consumables, including filter presses. Their products are used in various industries, including life sciences, healthcare, and environmental monitoring.

-

Spectrum Brands: Spectrum Brands is a leading manufacturer of filter presses, valves, and other process control equipment. Their products are used in a variety of industries, including food, beverage, and pharmaceuticals.

-

KSB Inc.: KSB Inc. is a leading manufacturer of filter presses, valves, and other process control equipment. Their products are used in a wide range of industries, including food, beverage, and pharmaceuticals.

Products and Services of Filter Press Manufacturers in the USA

Filter press manufacturers in the US offer a wide range of products and services, including:

-

Filter Presses: Filter presses are used to separate and concentrate liquids based on their physical and chemical properties. They are commonly used in the food, beverage, and pharmaceutical industries.

-

Valves: Valves are used to regulate the flow of fluids in various industries, including food, beverage, and pharmaceuticals.

-

Process Control Equipment: Process control equipment includes sensors, actuators, and other components that are used to monitor and control various processes.

-

Consumables: Consumables include filters, cartridges, and other components that are used to clean and maintain filter presses and other equipment.

-

Services: Many filter press manufacturers in the US offer services, including maintenance, repair, and calibration of their equipment.

Conclusion

Filter press manufacturers in the US play a vital role in the production of high-quality products in various industries. With the growing demand for efficient and effective filter presses, the industry is expected to continue growing in the coming years.

By understanding the top filter press manufacturers in the US, their products, and services, companies can make informed decisions about their equipment and operations.

How to Choose the Proper Filter Press Cloths?

Are you tired of using the wrong filter press cloths for your industrial needs? Choosing the right filter press cloths can be a daunting task, but with the right information, it can be a breeze. In this article, we will guide you through the process of selecting the proper filter press cloths for your specific needs.

How to Choose the Proper Filter Press Cloths

Choosing the right filter press cloths is crucial for the efficiency and effectiveness of your industrial processes. Here are some tips to help you make the right choice:

Consider the Material

The first thing to consider when choosing filter press cloths is the material. Different materials have different properties that make them suitable for specific applications. Here are some common materials used in filter press cloths:

-

Cotton: Cotton is a popular choice for filter press cloths due to its high strength, durability, and resistance to chemicals.

-

Polyester: Polyester is a synthetic material that is known for its resistance to heat, chemicals, and abrasion.

-

Stainless Steel Fiber: Stainless steel fiber is a high-quality material that is known for its corrosion resistance, strength, and durability.

Evaluate the Weight

The weight of the filter press cloths is another important factor to consider. The weight of the cloths will affect the filtration process, and a heavier cloth may be more effective in certain applications. Here are some common weight ranges for filter press cloths:

-

Lightweight: 100-200 gsm

-

Medium weight: 200-400 gsm

-

Heavyweight: 400-600 gsm

Assess the Thread Count

The thread count of the filter press cloths is also an important factor to consider. The thread count refers to the number of threads per square inch of fabric. Here are some common thread counts for filter press cloths:

-

Low thread count: 100-150 threads per square inch

-

Medium thread count: 150-200 threads per square inch

-

High thread count: 200-250 threads per square inch

Consider the Finish

The finish of the filter press cloths is another important factor to consider. Different finishes can affect the performance of the clothes in different applications. Here are some common finishes for filter press cloths:

-

Smooth finish: A smooth finish is ideal for applications where the clothes will be subjected to high pressure and temperature.

-

Textured finish: A textured finish is ideal for applications where the clothes will be subjected to high abrasion and wear.

Evaluate the Price

The price of the filter press cloths is another important factor to consider. Different materials and finishes can affect the price of the clothes. Here are some tips to help you evaluate the price of the clothes:

-

Compare Prices from different suppliers: Comparing prices from different suppliers can help you find the best deal.

-

Consider the cost per unit: Calculate the cost per unit to determine the most cost-effective option.