Posts Tagged: filter press machine

Boost Efficiency and Productivity with a Filter Press Machine

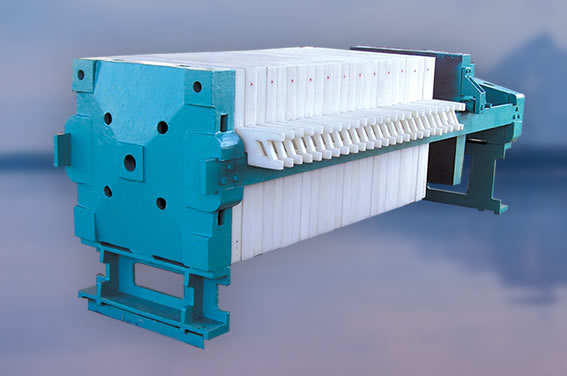

Discover the benefits of using a filter press machine for efficient solid-liquid separation in various industries. A filter press machine is a valuable tool that optimizes productivity by removing impurities from liquids and recovering valuable resources. In this article, we will explore the functionality, advantages, and applications of filter press machines.

Filter Press Machine: Enhancing Solid-Liquid Separation Efficiency

A filter press machine is a versatile equipment designed to separate solids from liquids efficiently. With its unique filtration process, this machine offers numerous benefits and finds applications in various industries, revolutionizing solid-liquid separation processes.

How Does a Filter Press Machine Work?

A filter press machine operates by applying pressure to a slurry or mixture of solids and liquids. The slurry is pumped into the machine, and the solids are gradually compacted and separated from the liquid phase through a series of filter plates. The filtered liquid, known as filtrate, is collected, while the solid residue, called filter cake, remains trapped in the plates. The filter cake is then removed, and the process continues.

Advantages of Using a Filter Press Machine

-

Efficient Solid-Liquid Separation:

A filter press machine offers high-efficiency solid-liquid separation, ensuring optimal removal of impurities and maximum recovery of valuable liquids or resources. This enhances product quality and reduces waste. -

Customizable Filtration Process:

Filter press machines allow for customization of filtration parameters such as pressure, temperature, and filter media selection. This adaptability enables precise control over the separation process, resulting in consistent and desired outcomes. -

Cost Savings:

By removing solids from liquids effectively, filter press machines minimize the volume of waste generated. This reduces disposal costs and contributes to a more sustainable and environmentally friendly operation. -

Increased Production Efficiency:

Filter press machines can handle large volumes of slurry and provide fast filtration rates. This boosts production efficiency, reduces processing time, and allows for continuous operation.

Applications of Filter Press Machines

-

Wastewater Treatment:

Filter press machines are widely used in wastewater treatment plants to separate solids from effluent, producing clean water for reuse or safe discharge. They play a crucial role in industries such as municipal wastewater treatment, mining, and food processing. -

Mining and Mineral Processing:

In mining operations, filter press machines are utilized to dewater slurry and recover valuable minerals from the extracted ore. These machines ensure efficient solid-liquid separation and enable the recycling and reuse of process water. -

Pharmaceutical and Chemical Industries:

Filter press machines find applications in pharmaceutical manufacturing and chemical processes, where the separation of solid particles from liquids is crucial for product quality and purity. They aid in the production of pharmaceuticals, chemicals, and specialty products.

Conclusion

In conclusion, a filter press machine is a powerful tool for enhancing solid-liquid separation efficiency in various industries. Its efficient filtration process, customizability, and cost-saving advantages make it indispensable for processes such as wastewater treatment, mining operations, and pharmaceutical manufacturing.

By incorporating a filter press machine into your operations, you can streamline processes, reduce waste, and achieve higher productivity. Embrace the benefits of a filter press machine and optimize your solid-liquid separation processes for improved efficiency and resource recovery.

Channel Presses For Sludge Dewatering

A PLC controls the stages and process durations for all the channel press capabilities including activity of the subordinate stuff.

The fluid or the uncooked cooking oil that should be separated is siphoned into the oil plant channel press with the help of an extraordinary strain siphon. The raw petroleum then misses through the focal hole and fills the chambers. Channel fabrics are available inside the chambers through which the crude oil passes.

Because of the fluctuation in porousness and surface region, each site’s material should be analyzed preceding measuring a Filter Press for a particular client programming. McLanahan gives talented lab and on location pilot testing with an expansive scope of testing capacities. Different boundaries are utilized for greenfield sites when it is unimaginable to expect to test. McLanahan Filter Presses are used by numerous every minute of every day activities that rely upon machine execution and great help to keep up with their harvests running and beneficial. This machine can adjust basically to entirely unexpected working circumstances and might be covered with exceptional supplies, especially when utilized as a pilot plant.

McLanahan Filter Presses embrace twin feed bays that lower delta speed and result in significantly less put on channel materials, as pleasantly as involving VELCRO® over regular zip-ties for simple other option. Unique FEATURES The Typeⅱ channel press is absolutely programmed framework equipped with a computerized channel cake end work and a programmed channel materials washing perform. Numerous strategies have been very much procured in assembling, squander water, and air contamination control. A channel cake eliminating transport, stage, a dribble skillet, etc can be found as a chance.

When the strain is bigger than the erosion obstruction of the tension plate, the strain plate gradually packs the channel plate.PP is constantly outside all together that residue will be cleaned effectively from PP cloth.Water accessibility and cost have gotten extra of a trouble as enormous populace regions proceed to develop.In numerous bigger limit channel squeezes, quick activity robotized plate shifters are utilized, speeding cycle time.

From that point forward, there have been extraordinary improvements in texture quality and assembling skill which have made this issue obsolete. Dissimilar to the US, electronic film channel innovation is the commonest strategy to dewater civil waste biosolids in Asia. Dampness is much of the time 10-15% lower and less polymer is required — which saves money on shipping and general removal cost. In oil sifting course of, outline and plate channel press is the super a portion of the framework. After increment of temperature of oil, earth added to lube test and blended. This oil and earth consolidated fluid is siphoned to channel press machine which has frame&plate sort plates and covered cotton channel press pieces of clothing with channel paper.

Our Services start from Concept Evaluation to Successful Oil Production. The hand pressure driven shutting component will incorporate a water driven chamber and hand worked water powered power pack. We can do a test to find out the answer for your particular application. Adaptable dewatering framework ideal for bigger throughput which can bear upping to the most extreme of conditions.

Besides, the cut off trickle plates especially channel the cleaning water while cleaning the channel plates and channel materials inside the press. To exhaust the channel press, the dribble plates ought to be opened up/eliminated to uncover the release chute for the channel cake. Channel presses are intended to convey a chose amount of material and separate the fluids and solids through strain filtration. A slurry is driven into the channel press and exposed to high strain for dewatering.

We production and commodity an extensive variety of channel presses with various limits. These filtration presses depend generally on the latest skill and convey best in class filtration results. Channel materials and its thickness performs fundamental situation in filtration nature of oil. With consistent give thought to the ongoing business sector, we convey forward an extraordinary differ filter press machine of Cast Iron Filter Press. Offered channel press is advanced using top notch inspected material and principal edge methodologies under the perception of prepared experts. This channel press is included with photograph electric light watches ensure employable security.

You are reminded to contact any outsiders to check information is precise, refreshed and complete prior to showing up upon it. SludgeProcessing.com acknowledges no legitimate liability regarding data presented by outsiders, moves made on the reason of this data or data hung on outsider sites. Channel press capacity arrangements could help you to remember putting away the hardware in right circumstances, as pleasantly as safeguarding the stuff customary activity. Channel Presses for Effluent Treatment Plant are manuafctured by us for get together Filtration of arranged types of Sludge either Industrial or Biological.

Verderflex siphons require no valves, seals or organs which makes them modest to keep up.

The kinds of filtrating is separated into open-stream filtrating and sub-current filtrating. Decrease or end of compound substances utilized for dewatering versus substitute innovations. As volume is added, square toes of floor space is relatively added and the cubic foot to square foot proportion stays fixed. To thwart spillage of the oil, ensure the line cuts are all fixed before start the machine.

At last the slurry can’t be siphoned in as a result of channel cake possesses the whole in the middle of between the chambers. As of now the channel plates are isolated either by mechanical or guide implies, regularly independently, permitting the channel cake to be released. Layer channel presses impact the dryness of the solid by using film innovation in the channel plates. Contrasted with ordinary filtration processes, it accomplishes the least leftover …

Channel Presses could be taken care of with centrifical siphons, two-stage centrifical siphons, hopeful relocation siphons, stomach siphons, screw siphons or a blend of those siphons. The determination of the right siphoning situation is basic to execution and working expenses. Since plate channel presses can go massively in estimation, the cost changes comprehensively furthermore.

Clarifiers are best depicted as enormous settling tanks, unmistakably utilized in the underlying dewatering segment. Here, water can enter at a ton decline solids concentrate, normally around 5-10 p.c solids. Utilizing gravity and polymers, clarifiers make solids develop on the lower part of the tank, where they are frequently released as muck. Flood tank or holding tank – Surge tanks are frequently used to permit Filter Presses, which work in a bunch course of, for use in a consistent course of. Flood tanks of various sizes could be considered to ensure a wipe and oversaw hyperlink out of your consistent cycle to the clump dewatering process.

At the point when the tension is more prominent than the rubbing opposition of the strain plate, the tension plate gradually packs the channel plate. Aside from our substance items, we also may assist with getting you arrangement with one of the most mind-blowing dewatering units, including the Matec channel press. At the point when utilized in blend with each other, a clarifier and channel press can recover % of your water as clear water. The excess water will release with the solids from the channel press. The two significant types of clarifiers are the flat rake type clarifier and the upward profound cone clarifier. Figuring out which sort of clarifier is most noteworthy for you is chosen by your explaining needs, determined by support costs, materials types and solids necessities.

Each channel press is described by having a channel floor and a maintenance amount of serious areas of strength for the, that rely upon the quantity of plates and their size might be pretty much monstrous. The channel press is a cluster kind handling machine highlighting various channel components working in equal. This kind of machine addresses the essential model of the channel presses given by Autemi. The opening and closing strides of the separating pack are executed by performing on the electrical control board …

Shriver® Filter PressThe Shriver® Filter Press is a basic member in streamlining your dewatering course of no matter what your exchange. Applications Metso VPA stress channels are produced for filtration of metallic minerals, modern minerals, coal and tailings. Flexible plates are utilized all together that channel texture can be cleaned just.

Made utilizing prime quality extra parts and components, these channels are in consistence with overall great necessities. To take special care of the different necessities of customers, we give these channels in a range of specs at reasonable charges. This sets aside cash and time by permitting the organization to lawfully sidestep release permitting and pink tape on the government, state, and local reaches. Kills water and sewer costs and any continuous yearly allowing and occasional testing charges for releasing modern waste waters.