Disc Stack Centrifuge: A Revolutionary Separation Technology

On December 15, 2023 by Megan Johnston With 0 Comments

- Blogging

The disc stack centrifuge is a cutting-edge separation technology that has gained widespread recognition in various industries. This revolutionary equipment has the potential to replace traditional separation methods.

What is a Disc Stack Centrifuge?

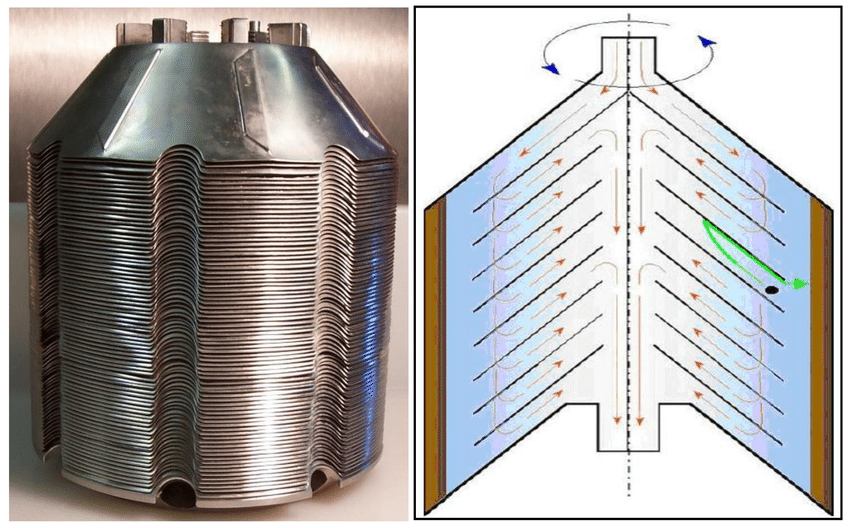

A disc stack centrifuge is a type of centrifuge that uses a stack of discs to separate particles or liquids of different densities or sizes. The discs are arranged in a vertical position and rotated at high speeds.

Creating a centrifugal force that separates the particles or liquids. The discs are designed with different hole sizes and shapes to accommodate various separation requirements.

Advantages of Disc Stack Centrifuges

Disc stack centrifuges offer several advantages over traditional separation methods, including:

-

Higher separation efficiency: Disc stack centrifuges can achieve higher separation efficiencies due to the unique design of the discs, which allows for better particle separation.

-

Cost-effectiveness: Disc stack centrifuges are more cost-effective than traditional methods, as they require less energy and maintenance.

-

Versatility: Disc stack centrifuges can be used for a wide range of applications, including liquid-liquid separation, solid-liquid separation, and particle separation.

Applications of Disc Stack Centrifuges

Disc stack centrifuges have numerous applications across various industries, including:

-

Chemical engineering: Disc stack centrifuges are used to separate chemicals and other particles in the chemical engineering industry.

-

Food and beverage: Disc stack centrifuges are used to separate liquids and particles in the food and beverage industry, such as in the production of fruit juices and dairy products.

-

Pharmaceuticals: Disc stack centrifuges are used to separate particles and liquids in the pharmaceutical industry, ensuring high-quality products.

-

Biotechnology: Disc stack centrifuges are used to separate biological particles and liquids in the biotechnology industry.

Examples of Disc Stack Centrifuge Applications

Some specific examples of disc stack centrifuge applications include:

-

Separating coffee beans from coffee grounds

-

Separating cornstarch from water

-

Separating blood cells from plasma

-

Separating bacteria from water

How to Choose the Right Disc Stack Centrifuge

Choosing the right disc stack centrifuge for your separation needs can be a challenge. Here are some factors to consider:

-

Capacity: Determine the capacity of the centrifuge you need, based on the volume of particles or liquids you need to separate.

- Disc size

and shape: Choose the appropriate disc size and shape for your separation requirements.

-

Rotational speed: Determine the rotational speed required for your separation needs.

-

Material: Choose a centrifuge made from materials that are compatible with your separation requirements, such as stainless steel or plastic.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting are essential to ensure your disc stack centrifuge operates efficiently and effectively. Here are some tips:

-

Regular cleaning and maintenance: Clean your centrifuge regularly and perform routine maintenance tasks to prevent wear and tear.

-

Troubleshooting guide: Keep a troubleshooting guide handy to help you identify and resolve common issues.

-

Professional assistance: Consult a professional if you encounter complex issues that you cannot resolve on your own.