How to Select Suitable Filter Cloth Specification for Clear Filtration

On December 8, 2023 by Megan Johnston With 0 Comments

- Blogging

Many industrial processes rely on filter cloth specifications, such as those for filtering, separation, and purification. Choosing the right filter cloth specification is essential for effective filtering, and we’ll go over all the factors to consider in this post to help you make that decision.

A First Look at Filter Cloth Specifications

An essential part of many industrial filtering systems, filter cloth is defined by a set of specifications that outline its qualities and characteristics.

The efficiency and effectiveness of filter cloth, a porous material used to remove solid particles from liquids or gases, are greatly affected by its specification.

Filter Cloth Models

To cater to various business needs, filter cloth specifications come in a variety of styles. These are a few examples of the most typical filter cloth specifications:

-

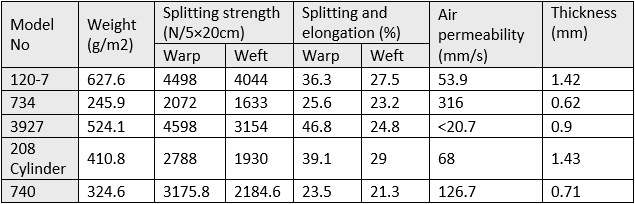

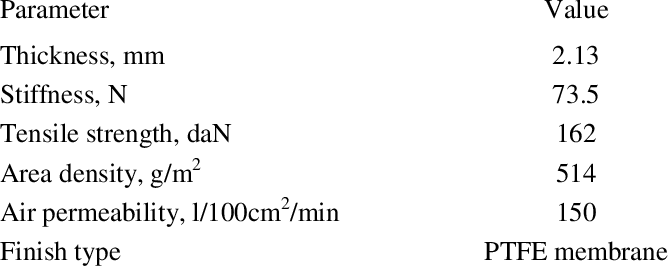

Rating in microns: This indicates the size, in microns, of the filter cloth’s pores. More fine filtering is possible with smaller pores and a higher micron rating, which is used to determine the size of particles that can pass through the filter cloth.

-

Fabric: Filter cloth is available in several different materials, including cotton, nylon, and polyester. Every material has its own set of benefits and drawbacks; picking one over another is a matter of determining the precise field of use.

-

Filter cloth is named for the pattern created by weaving together the yarns. The porosity, strength, and longevity of the filter fabric are all influenced by the weave.

-

Another important factor that determines the filter cloth’s efficacy and longevity is its thickness. Although thinner filter cloths may be more suited for low-pressure applications, thicker cloths can endure higher pressures and offer superior filtration.

Factors to Consider When Choosing the Specification of Filter Cloth

Several things should be thought about while choosing the filter fabric specification for clean filtering. Among these factors are:

Region of use: The filter cloth specification needed is determined by the region of use. To maintain product quality and purity, certain industries, such as those dealing with food and drink, may need filter cloths with higher micron ratings.

Particulate matter: The filter cloth specification is influenced by the particle size. For instance, a filter cloth with a higher micron rating might be necessary to capture extremely tiny particles.

In addition to the filter cloth’s dimensions, the flow rate of the filtered gas or liquid is another important consideration. To make sure the filter cloth can handle the pressure, a thicker cloth might be needed for a higher flow rate.

Another factor that impacts filter cloth specifications is the pressure drop over it. If the pressure drop is high, then the filter fabric needs to be thicker to handle it.

You should also think about how much the filter cloth standard will cost. The available budget will determine the specification of the filter cloth, as the cost of different materials and weaves can vary.

Pros of Using the Right Filter Cloth Specification

Several advantages can be achieved with the right filter cloth specification, such as:

-

Gaining the target degree of purity is easier with improved filtration efficiency, which can be accomplished with the right filter cloth specification.

-

Reducing the requirement for maintenance and downtime, increased productivity can be achieved with proper filter cloth specification.

-

Expense savings: By reducing waste and enhancing yields, the suitable filter cloth specification can help to save costs.

-

Higher-quality result: Accurate filter cloth specifications are a must for many industrial uses because they guarantee a high-quality result.