What is the difference between a belt dewatering press and a filter press?

On March 21, 2024 by Megan Johnston With 0 Comments

- Blogging

Belt dewatering press and filter press are both equipment used in various industries for solid-liquid separation. While they share some similarities, there are distinct differences between the two. In this article, we will explore the differences between a belt dewatering press and a filter press.

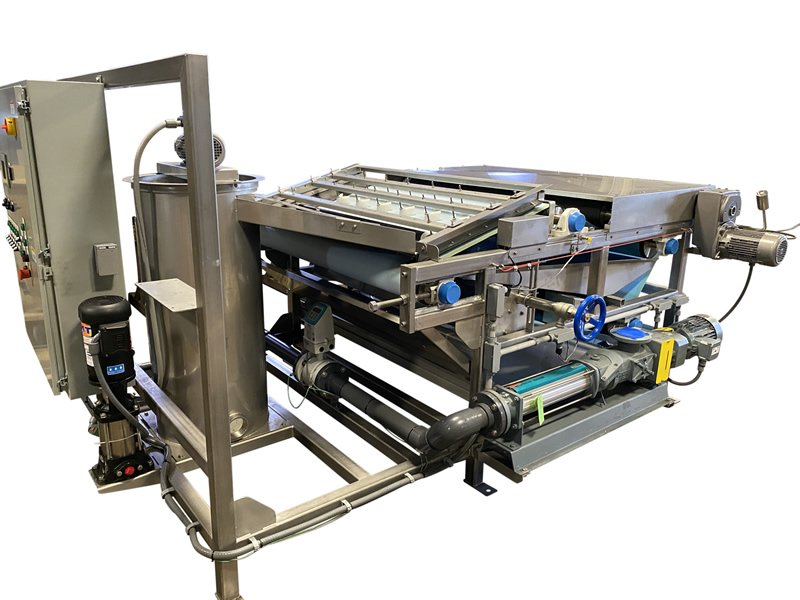

Belt Dewatering Press

A belt dewatering press is a type of equipment that uses a continuous belt to separate solids from liquids. The belt is made of a permeable material, such as polypropylene or polyester mesh, and is designed to allow liquids to pass through while retaining solids.

The belt is typically inclined at an angle, and the solids are loaded onto the belt through a feeding system. As the belt moves through the machine, the solids are subjected to a series of rollers that apply pressure to the solids, causing the liquids to be squeezed out. The dewatered solids are then discharged from the end of the belt, while the filtered liquids are collected in a tank for further treatment.

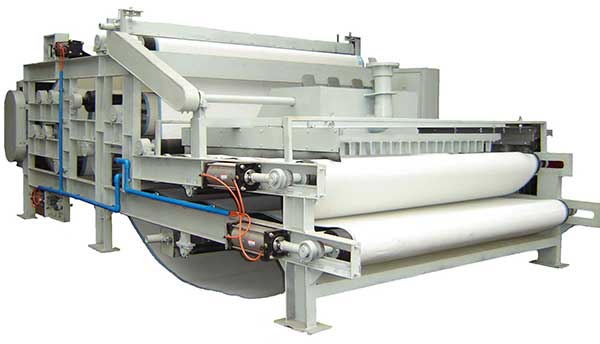

Filter Press

A filter press, on the other hand, is a type of equipment that uses a series of filters to separate solids from liquids. The filters are typically made of a porous material, such as paper or polypropylene, and are designed to allow liquids to pass through while retaining solids.

The filters are arranged in a stack, and the solids are loaded onto the top filter through a feeding system. As the liquids are pumped through the filters, the solids are retained on the surface of the filters, and the filtered liquids are collected in a tank for further treatment.

Differences between Belt Dewatering Press and Filter Press

The main difference between a belt dewatering press and a filter press is how the solids are separated from the liquids. In a belt dewatering press, the solids are separated from the liquids through a continuous belt, while in a filter press, the solids are separated from the liquids through a series of filters.

Additionally, the belt dewatering press uses a mechanical pressing action to remove liquids from the solids, while the filter press relies on the porosity of the filters to separate the solids from the liquids.

Another key difference between the two is the level of dewatering that can be achieved. Belt dewatering presses are typically able to achieve a higher level of dewatering than filter presses, as the mechanical pressing action can remove more liquids from the solids.

However, filter presses can achieve a higher level of purity in the filtered liquids, as the filters can remove finer particles and impurities from the liquids.