Skip to content

Posts By Megan Johnston

Introduct JingJin Filter Press About Applications and Benefits

On November 9, 2023 by Megan Johnston With 0 Comments

- Blogging

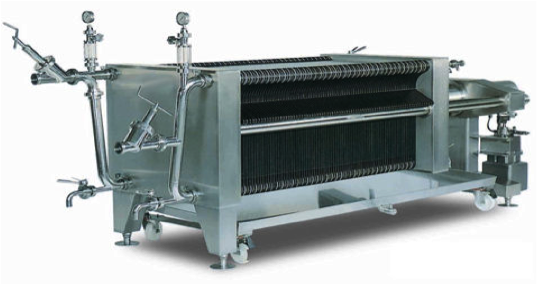

This article provides a comprehensive guide to the JingJin filter press, a highly efficient filtration system used in a wide range of industries. From understanding its working principle to exploring its applications and benefits, this guide covers everything you need to know about the JingJin filter press.

The Working Principle of JingJin Filter Press

JingJin filter press operates on the principle of pressure filtration. It consists of a series of filter plates and chambers that are tightly sealed. The slurry or liquid-solid mixture is pumped into the chambers, and pressure is applied to separate the solid particles from the liquid.

The filtered liquid, known as filtrate, flows through the filter cloth, while the solids are retained as a filter cake. The filter cake can then be discharged for further processing or disposal.

Applications of JingJin Filter Press

JingJin filter press finds applications in various industries, including:

-

Mining: In the mining industry, the JingJin filter press is used for dewatering mining concentrates, tailings, and other mining process slurries. It helps in recovering valuable minerals and reducing water content for efficient handling and disposal.

-

Chemical: JingJin filter press plays a vital role in the chemical industry to separate solids from liquids, such as in chemical processing, pigment production, and pharmaceutical manufacturing. It ensures product purity, reduces waste, and facilitates the recycling of valuable materials.

-

Wastewater Treatment: The JingJin filter press is widely used in wastewater treatment plants to dewater sludge and remove solid particles from the effluent. It helps in reducing the volume of waste and meeting regulatory requirements for water discharge.

Benefits of JingJin Filter Press

JingJin filter press offers several benefits in filtration processes:

-

Efficient Solid-Liquid Separation: With its high-pressure filtration capability, the JingJin filter press ensures efficient separation of solid particles from the liquid phase.

-

Reduced Moisture Content: By effectively removing water from slurry or sludge, the JingJin filter press reduces moisture content, resulting in cost savings in transportation and disposal.

-

Improved Product Quality: JingJin filter press helps in achieving higher product purity by effectively removing impurities and contaminants from liquids.

-

Environmental Sustainability: By reducing waste volume and facilitating the recycling of valuable materials, the JingJin filter press promotes environmental sustainability.

Conclusion

JingJin filter press is a reliable and efficient filtration system that finds applications in various industries. Its working principle, applications, and benefits make it an essential tool for solid-liquid separation processes.

Whether you are in the mining, chemical, or wastewater treatment industry, understanding the capabilities of the JingJin filter press can greatly enhance your filtration processes, leading to improved product quality, cost savings, and environmental sustainability.

Enhance Your Food Industry Operations with a Wholesale Food Filter Press

On November 6, 2023 by Megan Johnston With 0 Comments

- Blogging

This article serves as a comprehensive guide to wholesale food filter presses, essential equipment for optimizing food industry operations. Discover the benefits, applications, and considerations of using a wholesale food filter press in your food production or processing facility.

Introduction

In the food industry, maintaining product quality and meeting stringent regulatory standards are crucial. A wholesale food filter press is a powerful piece of equipment that plays a significant role in optimizing food production and processing operations.

This article explores the features, applications, and key considerations of using a wholesale food filter press in the food industry.

Benefits of a Wholesale Food Filter Press

A wholesale food filter press offers various advantages in food processing. It efficiently separates solids from liquids, ensuring the production of clarified juices, oils, and beverages.

This equipment helps improve product quality, extends shelf life, and enhances flavor profiles. Additionally, a wholesale food filter press reduces processing time, increases production efficiency, and ensures compliance with food safety regulations.

Applications of a Wholesale Food Filter Press

A wholesale food filter press finds applications in diverse areas of the food industry. It is commonly used for juice extraction, oil filtration, syrup clarification, and the production of alcoholic beverages.

This equipment effectively removes impurities, such as fruit pulp, sediments, and suspended solids, resulting in clear and visually appealing food products.

Considerations for Using a Wholesale Food Filter Press

When selecting and utilizing a wholesale food filter press, several considerations should be taken into account. These include the capacity and size of the equipment, the material compatibility with food products, and the ease of maintenance and cleaning.

It is crucial to choose a reputable supplier that offers reliable after-sales support and can provide customized solutions to meet specific food industry requirements.

Example Scenario

For example, in a juice production facility, a wholesale food filter press enables efficient extraction of clarified juice from fruits, removing pulp and solids. This equipment ensures the production of high-quality juices with improved clarity, taste, and nutritional value.

Additionally, by implementing a wholesale food filter press, the facility can streamline operations, minimize wastage, and meet the demands of a competitive market.

Conclusion

In conclusion, a wholesale food filter press is a valuable asset for food industry operations, enabling efficient separation of solids from liquids and ensuring high-quality food products.

By understanding the benefits, applications, and considerations of using a wholesale food filter press, food industry professionals can enhance their production processes, maintain product integrity, and meet regulatory requirements.

When selecting a wholesale food filter press, conduct thorough research and consider factors such as equipment capacity, compatibility with food products, and supplier reputation.

Collaborating with experienced industry professionals and equipment suppliers can provide valuable insights and ensure the successful integration of a wholesale food filter press into your food production or processing facility.

Efficient Filtration: Plate and Frame Filter for Optimal Results

On November 3, 2023 by Megan Johnston With 0 Comments

- Blogging

Discover the benefits of using a plate and frame filter for efficient filtration processes. This article highlights the advantages of plate and frame filters, including their versatility, high filtration capacity, and ease of maintenance.

Versatile Filtration Solution

Plate and frame filters offer a versatile solution for a wide range of industries and applications. Whether it’s removing impurities, clarifying liquids, or separating solids, these filters provide efficient filtration capabilities.

The design of plate and frame filters allows for customization, accommodating different filter media and sizes to suit specific filtration requirements. From pharmaceutical formulations to wine clarification, plate and frame filters deliver reliable and precise filtration results.

High Filtration Capacity

Plate and frame filters are known for their high filtration capacity. The arrangement of multiple plates in a frame creates a large filtration surface area, enabling efficient filtration of large volumes of liquid.

This increased capacity reduces filtration time and improves overall productivity. Whether you’re dealing with industrial-scale filtration processes or small-batch productions, plate and frame filters offer the capacity needed to handle the demands of your operations.

Easy Maintenance and Cleaning

Plate and frame filters are designed for easy maintenance and cleaning. The filter plates and frames can be easily disassembled, allowing for thorough cleaning and inspection.

The accessibility of the filter media simplifies replacement and ensures consistent filtration performance. With their user-friendly design, plate and frame filters minimize downtime during maintenance, maximizing operational efficiency and reducing costs associated with filter maintenance.

Precise Filtration Control

Plate and frame filters provide precise filtration control, allowing operators to adjust parameters such as pressure, flow rate, and filter media for optimal results. This control enables fine-tuning of the filtration process, ensuring the desired level of clarity and purity in the filtrate.

Whether it’s achieving specific particle size distribution or meeting stringent quality standards, plate and frame filters offer the flexibility and control needed to achieve precise filtration outcomes.

Example: Pharmaceutical Industry

In the pharmaceutical industry, plate and frame filters are widely used for the purification of active pharmaceutical ingredients (APIs) and the removal of impurities from drug formulations. These filters ensure the production of high-quality pharmaceutical products by effectively separating solids and contaminants.

From large-scale pharmaceutical manufacturing plants to research and development laboratories, plate and frame filters play a crucial role in maintaining product integrity and meeting regulatory requirements.

Example: Food and Beverage Applications

Plate and frame filters are essential in the food and beverage industry for the clarification of juices, wines, and other liquid products. These filters remove unwanted particles and sediments, resulting in clear and visually appealing beverages.

Plate and frame filters also contribute to the stability and shelf life of food and beverage products by eliminating spoilage microorganisms. From wineries to fruit juice processing plants, plate and frame filters ensure the production of high-quality, contaminant-free beverages.

Conclusion

Improve the efficiency and quality of your filtration processes with plate and frame filters. These filters offer versatility, high filtration capacity, and easy maintenance, making them suitable for various industries and applications.

With precise filtration control and customizable options, plate and frame filters provide optimal results in separating solids from liquids. Upgrade your filtration operations with plate and frame filters and experience the advantages of efficient filtration, enhanced productivity, and superior product quality.

Revolutionizing Wastewater Treatment with Sludge Dewatering Belt Press

On November 1, 2023 by Megan Johnston With 0 Comments

- Blogging

Wastewater treatment is a critical process for environmental protection and resource recovery. In this article, we explore the innovative technology of the sludge dewatering belt press.

The Power of Sludge Dewatering Belt Press

Sludge dewatering belt press, a game-changing technology, offers a sustainable solution for wastewater treatment plants and industries dealing with sludge. Its ability to effectively separate liquid from sludge has made it an essential component of modern wastewater treatment.

How the Sludge Dewatering Belt Press Works

The belt press operates by feeding sludge onto a porous belt that passes through a series of rollers. As the belt moves, pressure is applied to squeeze out the water, leaving behind dewatered sludge. This method is highly efficient, reducing the volume of sludge and facilitating easier disposal.

Advantages of Sludge Dewatering Belt Press

One of the primary advantages of the belt press is its cost-effectiveness. By significantly reducing the volume of sludge, it reduces disposal and transportation costs.

Additionally, the dewatered sludge can be repurposed for various applications, further saving resources and benefiting the environment.

Applications of Sludge Dewatering Belt Press

The belt press finds applications in a wide range of industries, including municipal wastewater treatment, food processing, and mining.

It is particularly valuable in wastewater treatment plants, where it efficiently handles large volumes of sludge and simplifies the treatment process.

Example of Efficiency in Municipal Wastewater Treatment

In a municipal wastewater treatment plant, the implementation of a sludge dewatering belt press led to a remarkable reduction in sludge volume.

This not only saved transportation costs but also reduced the environmental impact, as the dewatered sludge could be used for land application.

Conclusion

The sludge dewatering belt press is transforming the way we manage sludge in wastewater treatment and various industries. Its cost-effectiveness, efficiency, and versatility make it a crucial tool for reducing environmental impact and enhancing resource recovery.

By embracing this technology, organizations can optimize their sludge management processes while contributing to a more sustainable future.

In conclusion, the sludge dewatering belt press is a game-changing technology that offers efficient sludge management, cost savings, and environmental benefits.

With its ability to reduce sludge volume and repurpose dewatered sludge, it is becoming an essential component of wastewater treatment and various industries. Embracing this technology is a step toward a more sustainable and efficient future in sludge management.

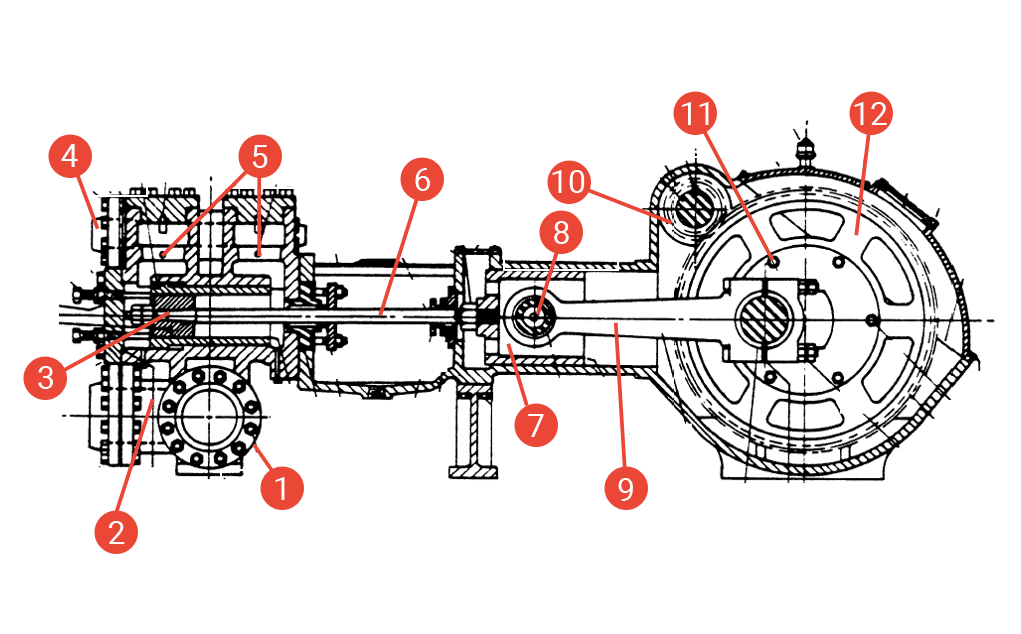

Reciprocating Plunger Pump: Efficient and Versatile Industrial Solution

On October 28, 2023 by Megan Johnston With 0 Comments

- Blogging

Explore the efficiency and versatility of reciprocating plunger pumps. This comprehensive article highlights the features, applications, and benefits of reciprocating plunger pumps.

Reciprocating Plunger Pump: Efficient and Versatile Industrial Solution

Reciprocating plunger pumps are essential equipment in industrial applications, offering efficient and precise fluid transfer solutions.

This article explores the features, applications, and advantages of reciprocating plunger pumps, showcasing their importance in achieving optimal performance in diverse industrial settings.

Features of Reciprocating Plunger Pump:

Efficient Fluid Transfer and Precision

Reciprocating plunger pumps are designed for efficient fluid transfer. They utilize a reciprocating motion to draw in and expel fluids, providing precise control and accuracy.

This feature makes them suitable for applications that require consistent flow rates or high-pressure fluid transfer, such as in oil and gas, chemical, or mining industries.

Applications of Reciprocating Plunger Pump:

- Oil and Gas Industry

Reciprocating plunger pumps play a vital role in the oil and gas industry, particularly in well-stimulation operations. They are used to inject fluids, such as water or chemicals, into oil or gas reservoirs to enhance production.

The precise control and high-pressure capabilities of reciprocating plunger pumps ensure efficient fluid injection and reservoir stimulation.

- Chemical Processing

In chemical processing plants, reciprocating plunger pumps are utilized for metering and transferring various chemicals. Their ability to handle corrosive and abrasive fluids makes them ideal for pumping chemicals in a controlled manner. Reciprocating plunger pumps ensure accurate dosing, maintaining process integrity and minimizing waste.

- Mining Operations

Reciprocating plunger pumps find application in mining operations, particularly for dewatering purposes. They efficiently remove water from mines, ensuring a safe and dry working environment.

The robust construction and high-pressure capabilities of reciprocating plunger pumps make them suitable for handling the demanding conditions of mining operations.

Advantages of Reciprocating Plunger Pump:

- Precise Flow Control

Reciprocating plunger pumps offer precise flow control, allowing for accurate dosing and consistent flow rates. This capability is crucial in applications where precise fluid transfer is essential, ensuring optimal process performance and minimizing product wastage.

- High Pressure Capability

Reciprocating plunger pumps are known for their ability to generate high pressures, making them suitable for applications that require pumping fluids against significant resistance.

Their high-pressure capabilities enable efficient fluid transfer and delivery in industries such as oil and gas, chemical processing, and mining.

- Versatility and Adaptability

Reciprocating plunger pumps are versatile and can handle a wide range of fluids, including corrosive, abrasive, or viscous substances.

They can be customized to meet specific project requirements, adapting to various industrial applications. Their versatility makes them a reliable choice for fluid transfer in diverse industries.

Conclusion:

In summary, reciprocating plunger pumps provide efficient and versatile fluid transfer solutions in industrial settings. Their precise flow control, high-pressure capabilities, and adaptability make them indispensable in the oil and gas, chemical, and mining industries.

Embrace the advantages of reciprocating plunger pumps to ensure reliable and accurate fluid transfer, enhancing productivity and performance in your industrial operations.

When selecting a reciprocating plunger pump, ensure that you choose a reputable manufacturer that offers high-quality products and comprehensive after-sales support. This will ensure optimal performance, longevity, and efficient operation of the pump.

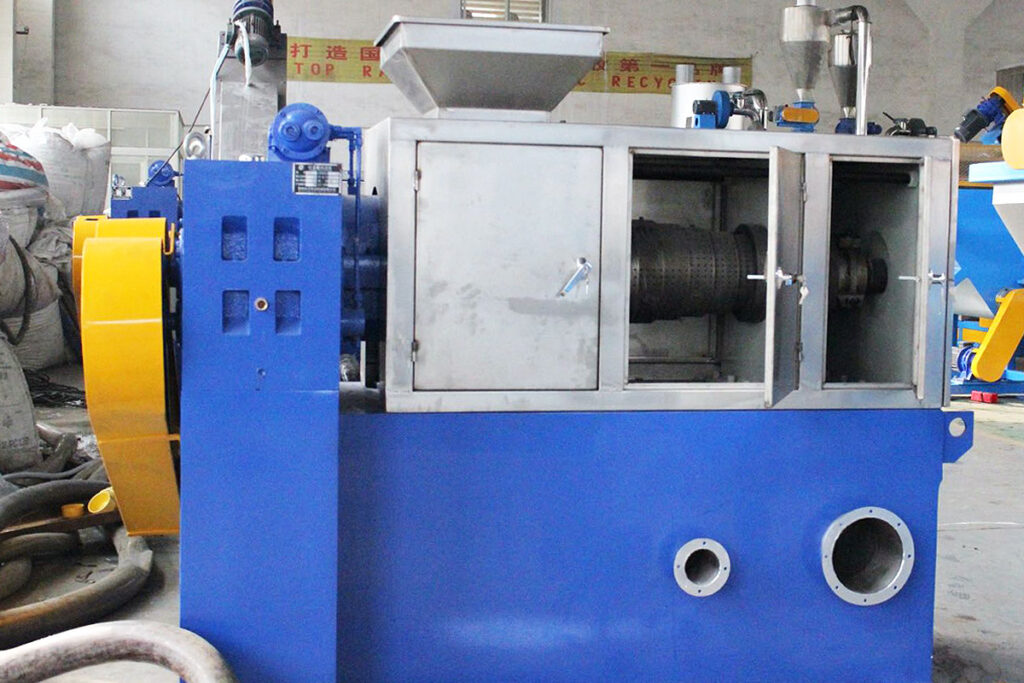

Revolutionize Dewatering Processes with a Dewatering Screw Press Machine

On October 25, 2023 by Megan Johnston With 0 Comments

- Blogging

From wastewater treatment plants to food processing industries, dewatering screw press machines offer reliable performance and cost-effective solutions. Learn how this equipment simplifies the dewatering process.

Introduction:

A dewatering screw press machine is a powerful tool used for efficient solid-liquid separation in various industries. This article explores the working principles, applications, and benefits of this innovative technology.

By understanding the capabilities and advantages of dewatering screw press machines, professionals can optimize their dewatering processes and achieve superior results.

I. What is a Dewatering Screw Press Machine?

A dewatering screw press machine is a mechanical device that uses a rotating screw to separate solids from liquids. It applies pressure to the material as it moves through the machine, forcing the liquid to pass through the screen or filter, while the solids are compacted and discharged.

This equipment is commonly used in wastewater treatment plants, food processing industries, pulp and paper mills, and other applications requiring efficient dewatering.

II. Working Principles and Benefits

-

Working Principles:

Dewatering screw press machines operate based on the Archimedean screw principle. The rotating screw pushes the material towards the discharge end while exerting pressure, effectively separating the liquid and solid components. The adjustable pressure and speed settings allow for precise control over the dewatering process. -

Efficient Solid-Liquid Separation:

One of the primary benefits of a dewatering screw press machine is its ability to achieve efficient solid-liquid separation. The rotating screw applies consistent pressure to the material, effectively removing moisture and reducing the volume of the solids. This results in drier cake solids and higher liquid recovery rates. -

Versatile Applications:

Dewatering screw press machines find applications in various industries. They are commonly used in wastewater treatment plants to dewater sludge and reduce disposal costs. In the food processing industry, these machines are utilized for separating liquids from fruit and vegetable pulp, dairy products, and other food byproducts.

III. Applications of Dewatering Screw Press Machines

-

Wastewater Treatment:

Dewatering screw press machines play a vital role in wastewater treatment plants, specifically in sludge dewatering processes.

They effectively remove water from sludge, reducing its volume and transforming it into a more manageable and transportable form. -

Food Processing:

In the food processing industry, dewatering screw press machines are utilized to separate liquids from various food byproducts.

They are commonly used in fruit and vegetable processing, dairy production, and other food manufacturing processes to extract liquids and reduce waste.

IV. Conclusion

Dewatering screw press machines offer an efficient and cost-effective solution for solid-liquid separation in various industries. Their ability to remove moisture and compact solids makes them indispensable in wastewater treatment plants and food processing facilities.

By implementing this innovative technology, professionals can streamline their dewatering processes, reduce disposal costs, and improve overall productivity. Whether you’re managing a wastewater treatment plant or overseeing a food processing operation, investing in a dewatering screw press machine can revolutionize your dewatering processes and deliver superior results.

Provoking Filtration Efficiency: Exploring the Function of a Filter Press Cloth

On October 20, 2023 by Megan Johnston With 0 Comments

- Blogging

This article provides an in-depth understanding of filter press cloth and its role in enhancing filtration efficiency. Explore the composition, benefits, and applications of filter press cloth.

Understanding Filter Press Cloth

Filter press cloth is a crucial component in filter press systems used for solid-liquid separation. It acts as a medium to capture and retain solid particles while allowing the liquid to pass through, resulting in efficient filtration processes.

Composition and Design

Filter press cloth is typically made of synthetic fibers, such as polypropylene, polyester, or nylon. These fibers are woven or non-woven to create a porous structure that can effectively trap solid particles during filtration. The design and weave pattern of the cloth plays a significant role in determining its filtration efficiency.

Enhancing Filtration Efficiency

Filter press cloth plays a vital role in enhancing filtration efficiency. Its porous structure allows for the effective retention of solid particles, ensuring high-quality filtrate. The selection of the appropriate cloth material and design is essential to achieve optimal filtration performance.

Diverse Applications

Filter press cloth finds applications in various industries, including wastewater treatment, chemical processing, mining, food and beverage, and pharmaceuticals. It is used to separate solids from liquids, remove impurities, and achieve desired product quality.

Example Scenario

For example, in a wastewater treatment plant, a filter press cloth is utilized in the filter press system to remove solid particles from the wastewater stream. The cloth captures the solids while allowing the treated water to pass through, resulting in clean and reusable water.

Conclusion:

Filter press cloth plays a critical role in achieving efficient solid-liquid separation in diverse industries. Its composition, design, and porosity contribute to optimal filtration performance.

Whether it’s wastewater treatment, chemical processing, or other applications requiring solid-liquid separation, selecting the right filter press cloth is crucial for achieving high-quality results.

Revolutionize Filtration with the Recessed Plate Filter Press

On October 17, 2023 by Megan Johnston With 0 Comments

- Blogging

Learn how this advanced filtration technology offers high-quality separation and dewatering of solids and liquids. Whether you’re in mining, chemical processing, or wastewater treatment, this article provides valuable insights into the recessed plate filter press and how it can optimize your filtration processes.

Introduction:

The recessed plate filter press is a game-changer in the field of filtration. This article delves into the working mechanism, benefits, and wide-ranging applications of this advanced filtration technology. Discover how the recessed plate filter press revolutionizes the separation and dewatering of solids and liquids, making it a preferred choice across industries.

Understanding the Recessed Plate Filter Press

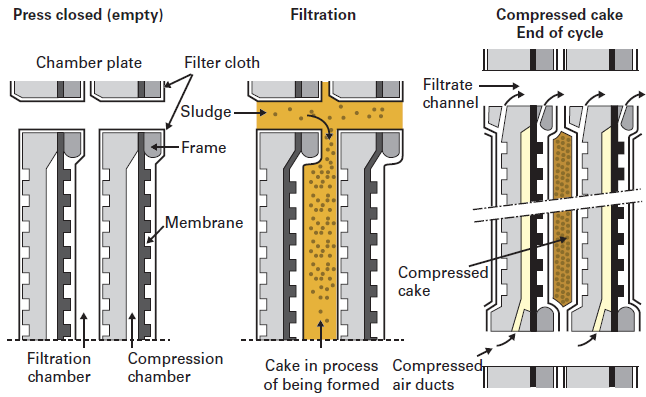

The recessed plate filter press is a specialized type of filter press designed for efficient solid-liquid separation. It operates using a series of recessed filter plates with interlocking edges, creating chambers for filtration. Key advantages of the recessed plate filter press include:

-

Efficient Filtration: The recessed plate design allows for optimal cake formation and effective separation of solids and liquids, resulting in high filtration efficiency.

-

Dewatering Capability: The filter press applies pressure to remove excess moisture from the filtered solids, resulting in improved dewatering efficiency.

Advantages of the Recessed Plate Filter Press

-

High Solids Retention: The recessed plate filter press excels at retaining a high volume of solids, ensuring maximum separation and reducing liquid waste.

-

Versatility: The filter press can handle a wide range of solid-liquid separation applications, including mining, chemical processing, pharmaceuticals, and wastewater treatment.

Applications of the Recessed Plate Filter Press

-

Mining Industry: The recessed plate filter press is widely used in mining operations for tailings dewatering, metal concentrate filtration, and environmental remediation.

-

Chemical Processing: Chemical manufacturers utilize the filter press for separating solids from liquids, clarifying solutions, and recovering valuable products.

-

Wastewater Treatment: Municipal and industrial wastewater treatment plants employ the recessed plate filter press for sludge dewatering, removing solids from effluent streams, and meeting regulatory requirements.

Examples of Recessed Plate Filter Press Applications

-

Mining Example: In a gold mine, the recessed plate filter press efficiently separates gold concentrate from the residual slurry, maximizing recovery and minimizing waste.

-

Chemical Processing Example: A chemical plant employs a recessed plate filter press to separate impurities from a chemical solution, ensuring product purity and meeting quality standards.

-

Wastewater Treatment Example: A wastewater treatment facility utilizes a recessed plate filter press to dewater sludge, reducing its volume for easier disposal and producing cleaner effluent.

In conclusion, the recessed plate filter press offers exceptional filtration efficiency and dewatering capabilities. Its versatile applications in mining, chemical processing, and wastewater treatment make it an indispensable tool for various industries. By adopting the recessed plate filter press, you can enhance your filtration system, achieve superior separation results, and optimize your operational processes.

Filter Plate Press: An Efficient Solution for Solid-Liquid Separation

On October 13, 2023 by Megan Johnston With 0 Comments

- Blogging

Looking for an efficient method for solid-liquid separation? The filter plate press is a versatile and reliable solution. In this article, we explore the key features and benefits of the filter plate press, as well as its applications in various industries.

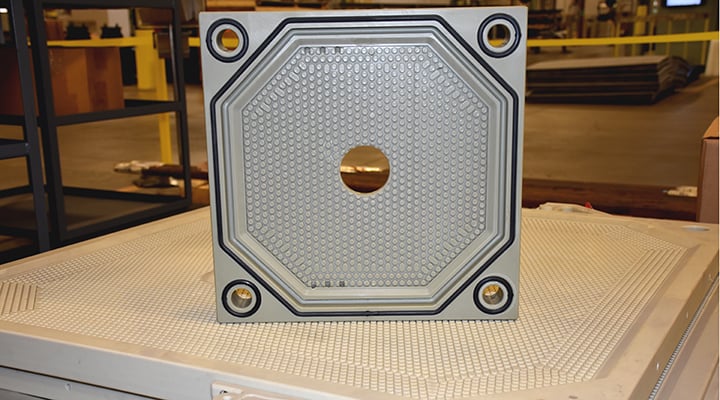

What is a Filter Plate Press?

The filter plate press is a specialized filtration equipment used for separating solid particles from liquid. It consists of a series of filter plates with filter media and a hydraulic system. The filter plates are arranged in a stack, and pressure is applied to force the liquid through the filter media, leaving behind the solid particles.

Key Features and Benefits of the Filter Plate Press

-

Efficient Filtration: The filter plate press offers high filtration efficiency, thanks to its large filtration area provided by multiple filter plates. It enables rapid separation and dewatering of solids, reducing processing time.

-

Customizable Design: Filter plate presses can be customized to suit specific filtration requirements. Different filter media, plate sizes, and configurations are available to accommodate various applications and optimize filtration performance.

-

Cost-Effective Solution: By efficiently removing solids from liquids, the filter plate press minimizes waste and reduces disposal costs. It also helps improve product quality and extends the lifespan of downstream equipment.

Applications of the Filter Plate Press

The filter plate press finds applications in numerous industries, including:

-

Wastewater Treatment: It effectively separates sludge from wastewater, facilitating the treatment process and ensuring compliance with environmental regulations.

-

Mining and Minerals: The filter plate press is used for dewatering mining concentrates and tailings, allowing for the recovery of valuable minerals and reducing water content for transport and disposal.

-

Chemical Processing: It plays a crucial role in separating solids from chemical solutions, enabling the production of high-quality products and minimizing product loss.

Example:

For instance, in the pharmaceutical industry, the filter plate press is utilized to separate solid impurities from liquid solutions during the production of drugs. By employing the filter plate press, pharmaceutical manufacturers can ensure the purity and safety of their products, meeting stringent regulatory requirements.

Conclusion:

The filter plate press is a reliable and efficient solution for solid-liquid separation. Its customizable design, high filtration efficiency, and wide range of applications make it a valuable asset across various industries. By incorporating a filter plate press into your filtration processes, you can achieve improved productivity, cost savings, and enhanced product quality.

In summary, the filter plate press offers an effective method for solid-liquid separation. Its customizable design, efficient filtration capabilities, and widespread applications make it an indispensable tool for industries seeking reliable and efficient filtration solutions.

Frame and Plate Filter: A Guide to Effective Filtration

On October 9, 2023 by Megan Johnston With 0 Comments

- Blogging

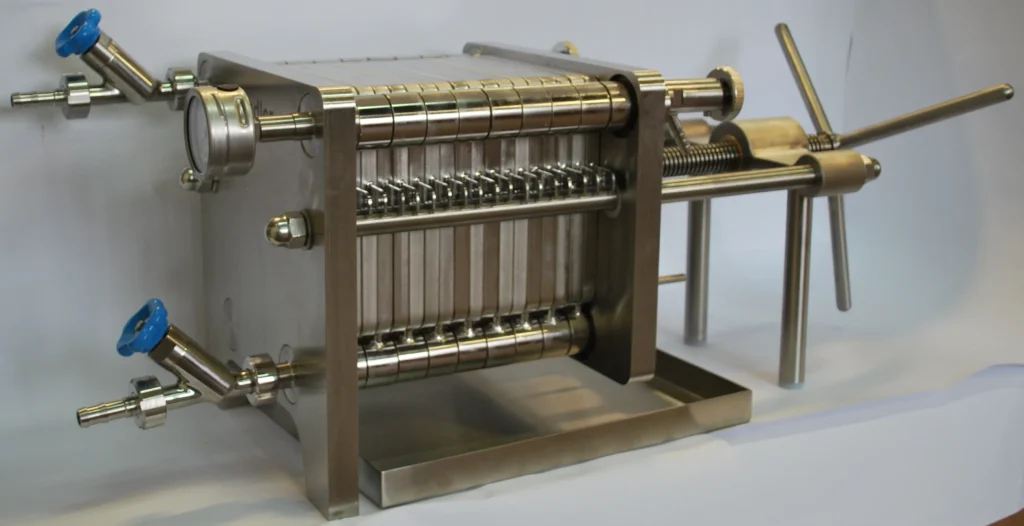

Frame and plate filters are versatile filtration systems used in various industries to remove impurities from liquids. We will discuss their working principles, key features, and specific applications. Whether you need to clarify beverages, recover valuable substances, or purify industrial fluids, this guide will help you understand why frame and plate filters are essential solutions.

Understanding Frame and Plate Filters:

Frame and plate filters consist of a series of plates and frames arranged alternately. The plates are covered with filter media, such as filter cloth or filter paper, which captures and retains impurities during the filtration process. The liquid is forced through the filter media, leaving behind the filtered solids.

Key Features and Advantages:

-

Versatile Filtration: Frame and plate filters are versatile and can be used for various filtration applications, including clarification, separation, and recovery of solids from liquids.

-

Efficient Filtration: The frame and plate design provide a large filtration area, ensuring efficient and high-capacity filtration. The filter media effectively captures and retains solids of different sizes.

-

Easy Maintenance: Frame and plate filters are easy to clean and maintain. The plates and frames can be easily removed for cleaning or replacement of the filter media.

-

Customizable Design: Frame and plate filters can be customized to meet specific requirements, such as the choice of filter media, plate material, and size. This allows for flexibility in adapting to different filtration processes.

Applications of Frame and Plate Filters:

-

Beverage Industry: Frame and plate filters are commonly used in the beverage industry for clarifying and polishing liquids such as wine, beer, and fruit juices. They remove suspended particles, yeast, and other impurities to improve the clarity and quality of the beverages.

-

Chemical and Pharmaceutical Industries: Frame and plate filters play a crucial role in the chemical and pharmaceutical sectors, where they are used for the separation, purification, and recovery of valuable substances from processed liquids.

-

Industrial Processes: Frame and plate filters find applications in various industrial processes, including wastewater treatment, oil and gas, food processing, and mining. They help remove particulate matter, contaminants, and solids from process fluids, ensuring product quality and process efficiency.