Skip to content

Posts Tagged: dewatering screw press machine

How Does a Dewatering Screw Press Machine Work?

On February 27, 2024 by Megan Johnston With 0 Comments

- Blogging

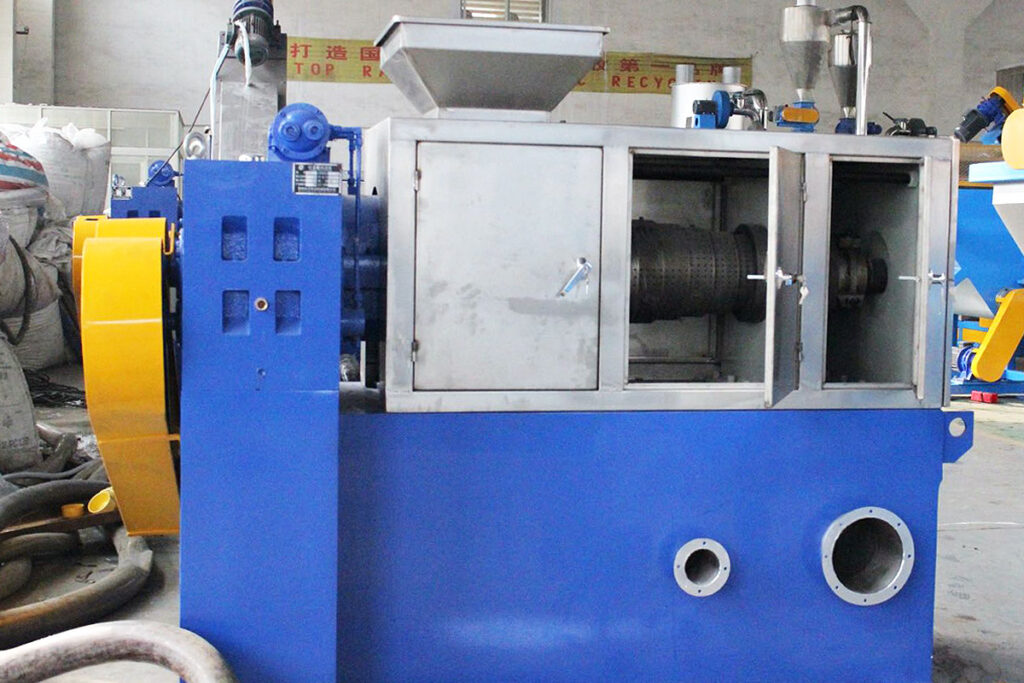

Dewatering screw press machines are widely used in various industries for solid-liquid separation. They are designed to remove excess water from materials, such as sludge, wastewater, and industrial slurries, to produce a dry, solid product. In this article, we will explore how a dewatering screw press machine works and its key components.

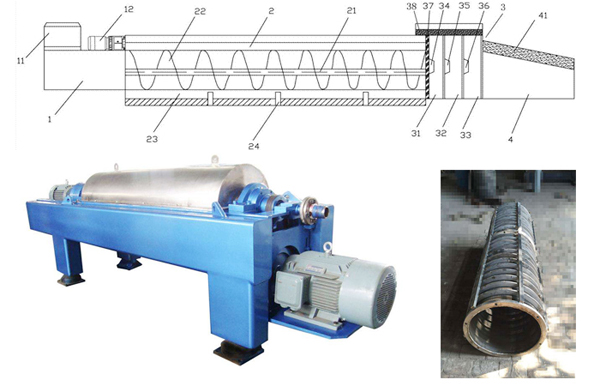

The Structure of a Dewatering Screw Press Machine

A dewatering screw press machine consists of a screw, a press plate, and a motor. The screw is the main component that drives the material through the machine, while the press plate applies pressure to the material to remove excess water. The motor powers the screw and press plate, allowing the machine to operate continuously.

The Working Process of a Dewatering Screw Press Machine

The working process of a dewatering screw press machine can be broken down into several stages:

Material Feeding: The material to be dewatered is fed into the machine through a hopper or a feeding system.

Screw Conveying: The screw conveys the material through the machine, creating a pressure difference between the front and rear of the screw.

Pressing: The press plate applies pressure to the material, causing the water to be squeezed out of the material.

Dewatering: The material is dewatered, and the excess water is collected in a tank or a container.

Discharge: The dewatered material is discharged from the machine through a discharge outlet.

Key Components of a Dewatering Screw Press Machine

The key components of a dewatering screw press machine include:

Screw: The screw is the main component that drives the material through the machine. It is typically made of a durable material, such as stainless steel or carbon steel.

Press Plate: The press plate applies pressure to the material to remove excess water. It is designed to withstand high pressure and is typically made of a wear-resistant material.

Motor: The motor powers the screw and press plate, allowing the machine to operate continuously.

Hopper: The hopper is the feeding system that supplies the material to the machine. It is designed to ensure a consistent flow of material into the machine.

Discharge Outlet: The discharge outlet is the opening through which the dewatered material is discharged from the machine.

Advantages of Dewatering Screw Press Machines

Dewatering screw press machines offer several advantages, including:

High Efficiency: Dewatering screw press machines are highly efficient and can produce a dry, solid product with a moisture content of less than 10%.

Cost-Effective: Dewatering screw press machines are cost-effective and can save money on energy and labor costs.

Versatility: Dewatering screw press machines can be used in various industries, including wastewater treatment, mining, and food processing.

Easy Maintenance: Dewatering screw press machines are easy to maintain and require minimal downtime for cleaning and maintenance.

Applications of Dewatering Screw Press Machines

Dewatering screw press machines have a wide range of applications, including:

Wastewater Treatment: Dewatering screw press machines are used to remove excess water from wastewater sludge, producing a dry, solid product that can be disposed of or used as fertilizer.

Mining: Dewatering screw press machines are used to remove excess water from mineral concentrates, such as iron ore and coal, to increase their weight and value.

Food Processing: Dewatering screw press machines are used to remove excess water from food products, such as fruit and vegetables, to increase their shelf life and quality.

Conclusion

In conclusion, dewatering screw press machines are an essential tool in various industries for solid-liquid separation. They offer high efficiency, cost-effectiveness, versatility, and ease of maintenance, making them a valuable investment for any industry that requires dewatering.

Revolutionize Dewatering Processes with a Dewatering Screw Press Machine

On October 25, 2023 by Megan Johnston With 0 Comments

- Blogging

From wastewater treatment plants to food processing industries, dewatering screw press machines offer reliable performance and cost-effective solutions. Learn how this equipment simplifies the dewatering process.

Introduction:

A dewatering screw press machine is a powerful tool used for efficient solid-liquid separation in various industries. This article explores the working principles, applications, and benefits of this innovative technology.

By understanding the capabilities and advantages of dewatering screw press machines, professionals can optimize their dewatering processes and achieve superior results.

I. What is a Dewatering Screw Press Machine?

A dewatering screw press machine is a mechanical device that uses a rotating screw to separate solids from liquids. It applies pressure to the material as it moves through the machine, forcing the liquid to pass through the screen or filter, while the solids are compacted and discharged.

This equipment is commonly used in wastewater treatment plants, food processing industries, pulp and paper mills, and other applications requiring efficient dewatering.

II. Working Principles and Benefits

-

Working Principles:

Dewatering screw press machines operate based on the Archimedean screw principle. The rotating screw pushes the material towards the discharge end while exerting pressure, effectively separating the liquid and solid components. The adjustable pressure and speed settings allow for precise control over the dewatering process. -

Efficient Solid-Liquid Separation:

One of the primary benefits of a dewatering screw press machine is its ability to achieve efficient solid-liquid separation. The rotating screw applies consistent pressure to the material, effectively removing moisture and reducing the volume of the solids. This results in drier cake solids and higher liquid recovery rates. -

Versatile Applications:

Dewatering screw press machines find applications in various industries. They are commonly used in wastewater treatment plants to dewater sludge and reduce disposal costs. In the food processing industry, these machines are utilized for separating liquids from fruit and vegetable pulp, dairy products, and other food byproducts.

III. Applications of Dewatering Screw Press Machines

-

Wastewater Treatment:

Dewatering screw press machines play a vital role in wastewater treatment plants, specifically in sludge dewatering processes.

They effectively remove water from sludge, reducing its volume and transforming it into a more manageable and transportable form. -

Food Processing:

In the food processing industry, dewatering screw press machines are utilized to separate liquids from various food byproducts.

They are commonly used in fruit and vegetable processing, dairy production, and other food manufacturing processes to extract liquids and reduce waste.