How Does a Dewatering Screw Press Machine Work?

On February 27, 2024 by Megan Johnston With 0 Comments

- Blogging

Dewatering screw press machines are widely used in various industries for solid-liquid separation. They are designed to remove excess water from materials, such as sludge, wastewater, and industrial slurries, to produce a dry, solid product. In this article, we will explore how a dewatering screw press machine works and its key components.

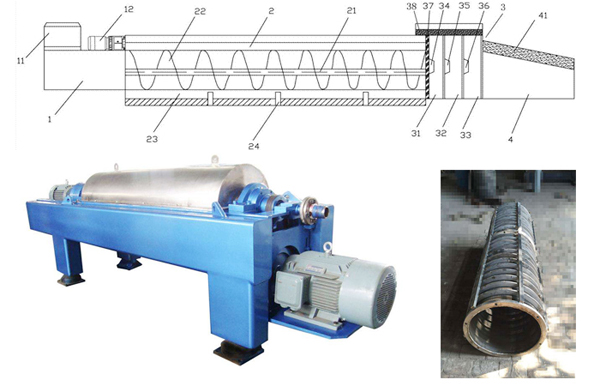

The Structure of a Dewatering Screw Press Machine

A dewatering screw press machine consists of a screw, a press plate, and a motor. The screw is the main component that drives the material through the machine, while the press plate applies pressure to the material to remove excess water. The motor powers the screw and press plate, allowing the machine to operate continuously.

The Working Process of a Dewatering Screw Press Machine

The working process of a dewatering screw press machine can be broken down into several stages:

Material Feeding: The material to be dewatered is fed into the machine through a hopper or a feeding system.

Screw Conveying: The screw conveys the material through the machine, creating a pressure difference between the front and rear of the screw.

Pressing: The press plate applies pressure to the material, causing the water to be squeezed out of the material.

Dewatering: The material is dewatered, and the excess water is collected in a tank or a container.

Discharge: The dewatered material is discharged from the machine through a discharge outlet.

Key Components of a Dewatering Screw Press Machine

The key components of a dewatering screw press machine include:

Screw: The screw is the main component that drives the material through the machine. It is typically made of a durable material, such as stainless steel or carbon steel.

Press Plate: The press plate applies pressure to the material to remove excess water. It is designed to withstand high pressure and is typically made of a wear-resistant material.

Motor: The motor powers the screw and press plate, allowing the machine to operate continuously.

Hopper: The hopper is the feeding system that supplies the material to the machine. It is designed to ensure a consistent flow of material into the machine.

Discharge Outlet: The discharge outlet is the opening through which the dewatered material is discharged from the machine.

Advantages of Dewatering Screw Press Machines

Dewatering screw press machines offer several advantages, including:

High Efficiency: Dewatering screw press machines are highly efficient and can produce a dry, solid product with a moisture content of less than 10%.

Cost-Effective: Dewatering screw press machines are cost-effective and can save money on energy and labor costs.

Versatility: Dewatering screw press machines can be used in various industries, including wastewater treatment, mining, and food processing.

Easy Maintenance: Dewatering screw press machines are easy to maintain and require minimal downtime for cleaning and maintenance.