Boost Efficiency and Productivity with a Filter Press Machine

On September 22, 2023 by Megan Johnston With 0 Comments

- Blogging

Discover the benefits of using a filter press machine for efficient solid-liquid separation in various industries. A filter press machine is a valuable tool that optimizes productivity by removing impurities from liquids and recovering valuable resources. In this article, we will explore the functionality, advantages, and applications of filter press machines.

Filter Press Machine: Enhancing Solid-Liquid Separation Efficiency

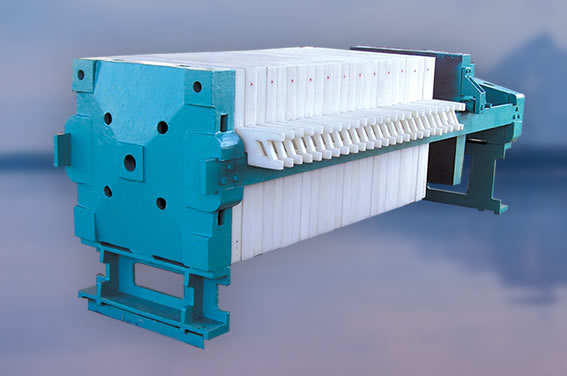

A filter press machine is a versatile equipment designed to separate solids from liquids efficiently. With its unique filtration process, this machine offers numerous benefits and finds applications in various industries, revolutionizing solid-liquid separation processes.

How Does a Filter Press Machine Work?

A filter press machine operates by applying pressure to a slurry or mixture of solids and liquids. The slurry is pumped into the machine, and the solids are gradually compacted and separated from the liquid phase through a series of filter plates. The filtered liquid, known as filtrate, is collected, while the solid residue, called filter cake, remains trapped in the plates. The filter cake is then removed, and the process continues.

Advantages of Using a Filter Press Machine

-

Efficient Solid-Liquid Separation:

A filter press machine offers high-efficiency solid-liquid separation, ensuring optimal removal of impurities and maximum recovery of valuable liquids or resources. This enhances product quality and reduces waste. -

Customizable Filtration Process:

Filter press machines allow for customization of filtration parameters such as pressure, temperature, and filter media selection. This adaptability enables precise control over the separation process, resulting in consistent and desired outcomes. -

Cost Savings:

By removing solids from liquids effectively, filter press machines minimize the volume of waste generated. This reduces disposal costs and contributes to a more sustainable and environmentally friendly operation. -

Increased Production Efficiency:

Filter press machines can handle large volumes of slurry and provide fast filtration rates. This boosts production efficiency, reduces processing time, and allows for continuous operation.

Applications of Filter Press Machines

-

Wastewater Treatment:

Filter press machines are widely used in wastewater treatment plants to separate solids from effluent, producing clean water for reuse or safe discharge. They play a crucial role in industries such as municipal wastewater treatment, mining, and food processing. -

Mining and Mineral Processing:

In mining operations, filter press machines are utilized to dewater slurry and recover valuable minerals from the extracted ore. These machines ensure efficient solid-liquid separation and enable the recycling and reuse of process water. -

Pharmaceutical and Chemical Industries:

Filter press machines find applications in pharmaceutical manufacturing and chemical processes, where the separation of solid particles from liquids is crucial for product quality and purity. They aid in the production of pharmaceuticals, chemicals, and specialty products.