Skip to content

Posts Tagged: China FEP Tubing suppliers

What factors influence the selection of FEP Tubing over seamless tubing?

On April 28, 2024 by Megan Johnston With 0 Comments

- Blogging

The selection of FEP (Fluorinated Ethylene Propylene) tubing over seamless tubing can be influenced by several factors, including:

- Chemical Resistance: FEP tubing offers excellent chemical resistance to a wide range of corrosive chemicals, solvents, and acids. This makes it suitable for applications where exposure to harsh chemicals is a concern. Seamless tubing may not offer the same level of chemical resistance, particularly if made from materials like metals or non-fluorinated polymers.

- Temperature Resistance: FEP tubing has a high operating temperature range, typically from -70°C to 200°C (-94°F to 392°F), making it suitable for use in both low and high-temperature environments. Seamless tubing materials may have lower temperature resistance limits, restricting their use in extreme temperature conditions.

- Non-Stick Properties: FEP tubing has excellent non-stick properties, which reduce the buildup of residue or contaminants on the inner surface of the tubing. This property is advantageous in applications where cleanliness and purity are critical, such as in pharmaceutical, food processing, and semiconductor industries. Seamless tubing may be more prone to fouling or contamination due to its surface properties.

- Flexibility: FEP tubing is highly flexible and can be easily manipulated or bent without kinking or collapsing. This flexibility allows for easy installation in tight spaces or complex routing paths. Seamless tubing may be less flexible and may require additional fittings or connectors to achieve desired configurations.

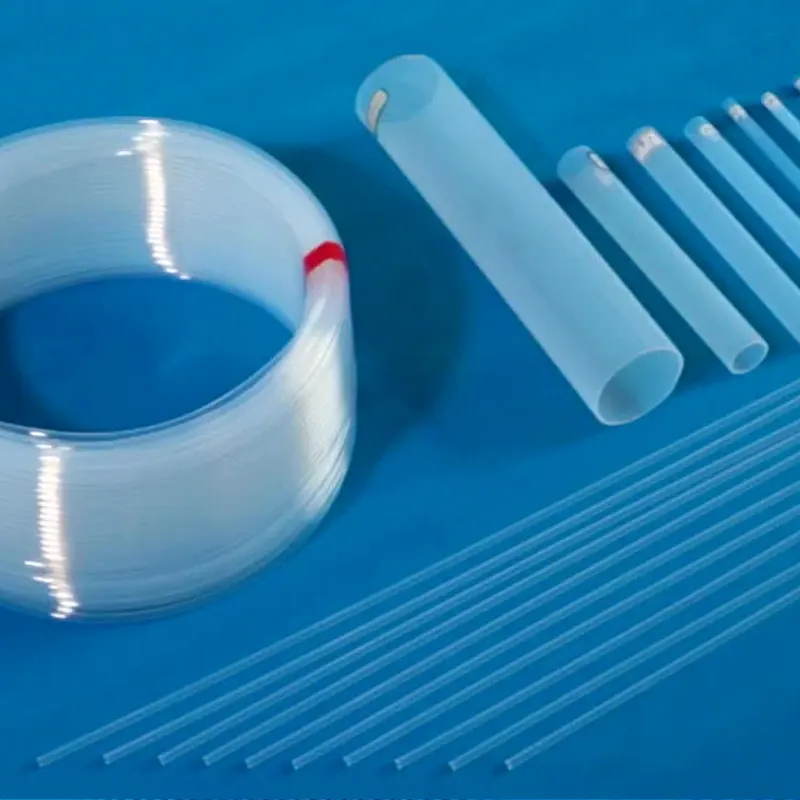

- Transparency: FEP tubing is transparent, allowing for visual inspection of fluid flow or contents. China FEP Tubing suppliers This transparency is beneficial in applications where monitoring or visualization of processes is necessary. Seamless tubing materials may not offer the same level of transparency, making it challenging to observe flow or detect any issues.

- Electrical Insulation: FEP tubing exhibits excellent electrical insulation properties, making it suitable for use in electrical and electronic applications where insulation and protection of wires or components are required. Seamless tubing materials may not provide the same level of electrical insulation.

- FDA Compliance: FEP tubing is often FDA (Food and Drug Administration) compliant for use in food and beverage applications where regulatory compliance is essential. Seamless tubing may not meet the necessary regulatory requirements for food contact applications.

- Cost: The cost of FEP tubing may vary depending on factors such as diameter, wall thickness, and length. In some cases, FEP tubing may be more cost-effective than seamless tubing materials, especially when considering factors such as chemical resistance, temperature range, and performance characteristics.

Overall, the selection of FEP tubing over seamless tubing depends on specific application requirements, such as chemical resistance, temperature range, flexibility, transparency, electrical insulation, regulatory compliance, and cost considerations. FEP tubing is preferred in applications where these properties are critical for optimal performance and reliability.