Skip to content

Posts Tagged: filter press cloths

How to Choose the Proper Filter Press Cloths?

On January 2, 2024 by Megan Johnston With 0 Comments

- Blogging

Are you tired of using the wrong filter press cloths for your industrial needs? Choosing the right filter press cloths can be a daunting task, but with the right information, it can be a breeze. In this article, we will guide you through the process of selecting the proper filter press cloths for your specific needs.

How to Choose the Proper Filter Press Cloths

Choosing the right filter press cloths is crucial for the efficiency and effectiveness of your industrial processes. Here are some tips to help you make the right choice:

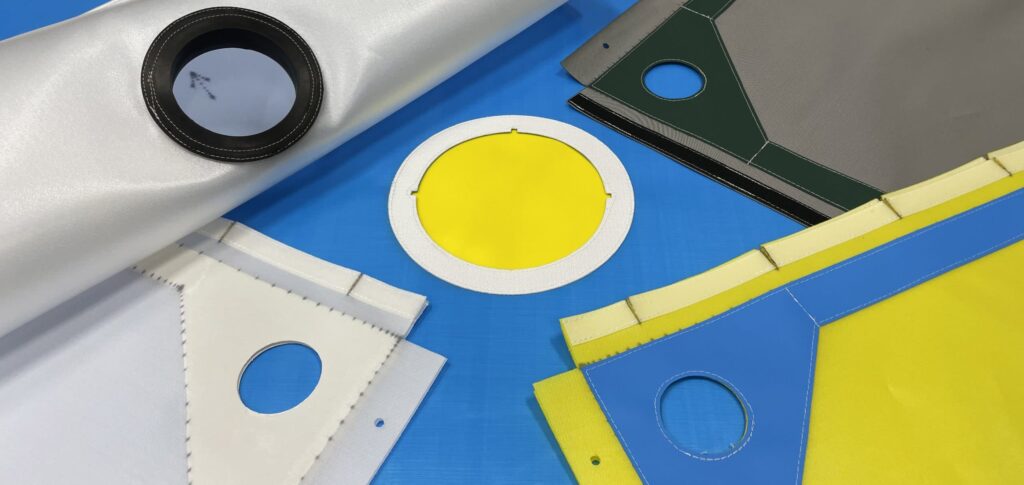

Consider the Material

The first thing to consider when choosing filter press cloths is the material. Different materials have different properties that make them suitable for specific applications. Here are some common materials used in filter press cloths:

-

Cotton: Cotton is a popular choice for filter press cloths due to its high strength, durability, and resistance to chemicals.

-

Polyester: Polyester is a synthetic material that is known for its resistance to heat, chemicals, and abrasion.

-

Stainless Steel Fiber: Stainless steel fiber is a high-quality material that is known for its corrosion resistance, strength, and durability.

Evaluate the Weight

The weight of the filter press cloths is another important factor to consider. The weight of the cloths will affect the filtration process, and a heavier cloth may be more effective in certain applications. Here are some common weight ranges for filter press cloths:

-

Lightweight: 100-200 gsm

-

Medium weight: 200-400 gsm

-

Heavyweight: 400-600 gsm

Assess the Thread Count

The thread count of the filter press cloths is also an important factor to consider. The thread count refers to the number of threads per square inch of fabric. Here are some common thread counts for filter press cloths:

-

Low thread count: 100-150 threads per square inch

-

Medium thread count: 150-200 threads per square inch

-

High thread count: 200-250 threads per square inch

Consider the Finish

The finish of the filter press cloths is another important factor to consider. Different finishes can affect the performance of the clothes in different applications. Here are some common finishes for filter press cloths:

-

Smooth finish: A smooth finish is ideal for applications where the clothes will be subjected to high pressure and temperature.

-

Textured finish: A textured finish is ideal for applications where the clothes will be subjected to high abrasion and wear.

Evaluate the Price

The price of the filter press cloths is another important factor to consider. Different materials and finishes can affect the price of the clothes. Here are some tips to help you evaluate the price of the clothes:

-

Compare Prices from different suppliers: Comparing prices from different suppliers can help you find the best deal.

-

Consider the cost per unit: Calculate the cost per unit to determine the most cost-effective option.

Conclusion:

Choosing the proper filter press cloths for your industrial needs can be a challenging task, but with the right information, it can be a breeze. By considering the material, weight, thread count, finish, and price.

You can find the best clothes for your specific needs. Remember to evaluate your options carefully and choose the clothes that offer the best balance of quality and cost.

Enhancing Filtration Efficiency with Quality Filter Press Cloths

On November 22, 2023 by Megan Johnston With 0 Comments

- Blogging

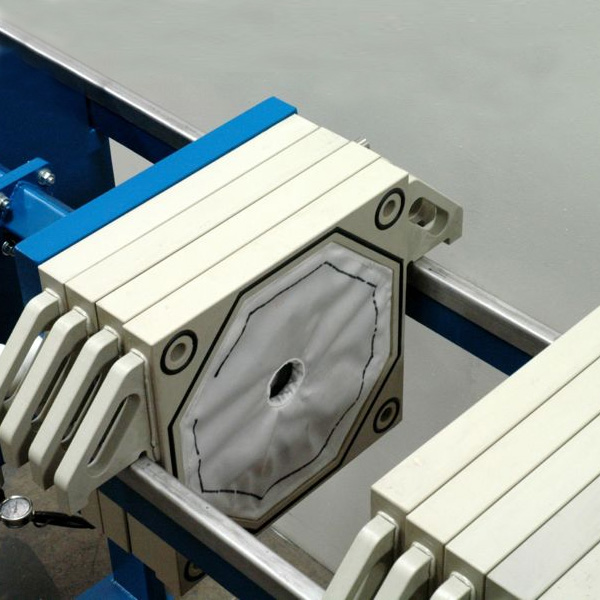

Filter press cloths play a crucial role in optimizing filtration processes by effectively separating solids from liquids. This article provides valuable insights into the importance of filter press cloths, their benefits, and considerations for selecting high-quality cloths.

The Significance of Filter Press Cloths

Filter press cloths offer several benefits for efficient filtration:

-

Solid-Liquid Separation: Filter press cloths act as a barrier, allowing liquid to pass through while retaining solid particles, ensuring effective separation and efficient filtration.

-

Improved Filtration Efficiency: High-quality filter press cloths enhance filtration efficiency by providing uniform and controlled filtration rates, resulting in optimized throughput and reduced cycle times.

-

Enhanced Cake Release: The right selection of filter press cloths promotes easy cake release, preventing clogging and ensuring continuous operation.

Selecting Quality Filter Press Clothes

Consider the following factors when choosing filter press cloths:

-

Material Composition: Select filter press cloths made from durable and chemically resistant materials, such as polypropylene, polyester, or nylon, based on the specific filtration application and the nature of the filtered substances.

-

Micron Rating: Determine the desired micron rating based on the size of the particles to be filtered. Different applications require varying levels of filtration precision.

-

Cloth Design and Weave: Evaluate the cloth design and weave pattern to ensure uniform and controlled filtration, preventing particle breakthroughs and promoting efficient cake formation.

Applications of Filter Press Cloths

Filter press cloths find extensive applications across various industries:

-

Chemical and Pharmaceutical: Filter press cloths are used in chemical and pharmaceutical manufacturing processes to separate solids from liquids, ensuring high product quality and purity.

-

Mining and Metallurgy: Cloths play a vital role in mining and metallurgical operations, facilitating the separation of valuable minerals from slurries.

-

Food and Beverage: Filter press cloths are utilized in the food and beverage industry to clarify liquids, remove impurities, and achieve desired product clarity.

Example of Filter Press Cloths in Action

In a wastewater treatment plant, filter press cloths are employed to remove solid particles from sludge, ensuring cleaner water discharge. The cloths capture the solid debris, allowing for the separation of clean water, which can be recycled or safely released into the environment.

Conclusion

Filter press cloths are essential components in optimizing filtration processes, facilitating efficient solid-liquid separation. By selecting high-quality filter press cloths based on material composition, micron rating, and cloth design, industries can enhance filtration efficiency and achieve superior results.

From chemical and pharmaceutical manufacturing to mining and food processing, filter press cloths find applications in various industries, ensuring reliable and effective filtration.

Filter Press Cloth Types: A Comprehensive Guide

On August 15, 2023 by Megan Johnston With 0 Comments

- Blogging

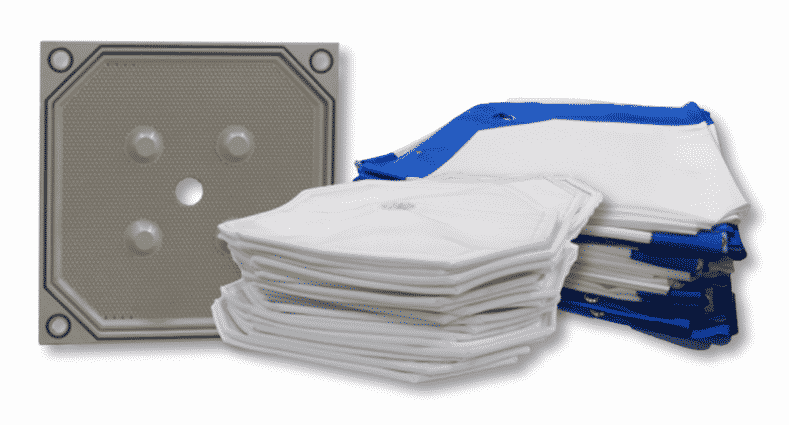

Choosing the right filter press cloth is crucial for optimizing filtration efficiency and achieving desired separation results. This article serves as a comprehensive guide to understanding different filter press cloth types. From woven and non-woven fabrics to their specific applications, we’ll explore the characteristics and benefits of each type.

Woven Filter Press Cloths

Woven filter press cloths are made from interlaced threads, offering excellent strength and durability. They are available in various materials, such as polypropylene, polyester, and nylon, each with unique properties suitable for different filtration processes.

Polypropylene Filter Press Cloths

Polypropylene filter press cloths are widely used due to their chemical resistance, high tensile strength, and excellent cake release properties. They are ideal for applications involving acidic or alkaline solutions, such as chemical processing and wastewater treatment.

Polyester Filter Press Cloths

Polyester filter press cloths are known for their resistance to abrasion and high temperatures. They are commonly used in applications where the filtration process involves hot liquids or aggressive chemicals, such as pharmaceuticals and food processing.

Non-Woven Filter Press Cloths

Non-woven filter press cloths are made from fibers bonded together, offering unique filtration properties. They are available in different materials and configurations, providing versatility and efficiency in specific applications.

Polypropylene Non-Woven Filter Press Cloths

Polypropylene non-woven filter press cloths are known for their excellent particle retention and cake release properties. They are often used in industries such as mining, metallurgy, and coal processing, where high solids retention is crucial.