Skip to content

Posts Tagged: Hydraulic Filter Press

Hydraulic Filter Press: Working Principle and Advantages

On December 26, 2023 by Megan Johnston With 0 Comments

- Blogging

This article provides an overview of the hydraulic filter press’s operation and benefits in many sectors. It also goes over the advantages of employing a hydraulic filter press and how it may boost the efficiency and efficacy of filtration procedures.

Hydraulic Filter Press Operation

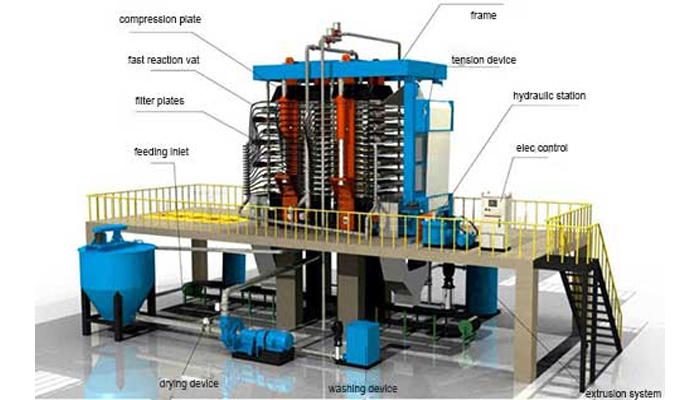

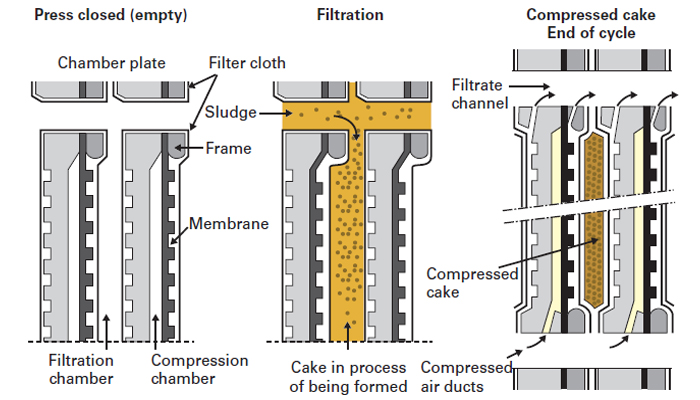

A hydraulic filter press is a device that separates particles from liquids by using hydraulic pressure. The filter pack is made up of a succession of plates and frames that are stacked together.

The plates have a series of pores that allow liquid to pass through while inhibiting solids. The filter pack is subjected to hydraulic pressure, which drives the liquid to pass through the plates while leaving the particulates behind.

Hydraulic Filter Press Benefits

There are various advantages to using a hydraulic filter press over traditional filtration methods. One of its primary benefits is its capacity to handle high-pressure and high-flow rate applications.

The hydraulic filter press can handle pressures up to 1000 psi and flow rates up to 1000 gpm, making it excellent for chemical, petrochemical, and oil refining applications.

The hydraulic filter press also can remove a wide spectrum of pollutants. The device can eliminate contaminants as small as 0.01 microns and as large as 100 microns, making it appropriate for a wide range of applications.

Furthermore, the hydraulic filter press is simple to operate and maintain because it requires little human intervention and is readily cleaned and serviced.

Hydraulic Filter Press Applications

The hydraulic filter press has numerous applications in a variety of sectors, including:

Chemical processing: The hydraulic filter press is used to remove impurities such as sulfur, carbon, and other pollutants from chemicals.

Petrochemical processing: The device is used to remove impurities such as water, salt, and other pollutants from crude oil.

Oil refining: The hydraulic filter press is used in oil refining to remove impurities such as water, carbon, and other pollutants from the oil.

Food and beverage processing: The device is used to eliminate impurities such as yeast, bacteria, and other pollutants from food and beverages.

Conclusion:

Finally, the hydraulic filter press is a versatile instrument that provides numerous advantages in a variety of sectors. It is an excellent choice for filtration processes due to its capacity to handle high-pressure and high-flow rate applications, remove a wide range of pollutants, and ease of operation and maintenance.

Industries can increase the efficiency and efficacy of their filtration operations by knowing the working principle and benefits of the hydraulic filter press, resulting in higher quality products and lower costs.

What is a Hydraulic Filter Press and How Does it Work?

On December 4, 2023 by Megan Johnston With 0 Comments

- Blogging

A hydraulic filter press is a type of filter press that uses hydraulic pressure to separate solids from liquids. It is widely used in various industries such as chemical, petrochemical, pharmaceutical, and food and beverage.

How a Hydraulic Filter Press Works

A hydraulic filter press consists of a series of plates and frames that are alternately pressed together to form a chamber. The liquid to be filtered is pumped into the chamber, and the solids are trapped in the filter press.

The hydraulic pressure is then applied to the plates, which forces the liquid through the filter press, leaving the solids behind. The filtered liquid is then collected, and the solids are removed from the filter press.

Advantages of Hydraulic Filter Press

The hydraulic filter press has several advantages over other types of filter presses. One of the main advantages is its high filtration efficiency.

The hydraulic pressure ensures that the liquid is forced through the filter press, leaving no room for impurities to pass through. This results in a higher quality of filtration, making it ideal for applications where high purity is required.

Another advantage of the hydraulic filter press is its versatility. It can be used to filter a wide range of liquids, from water to oil, and from chemicals to food and beverage. It is also easy to operate and maintain, making it a cost-effective solution for many industries.

Applications of Hydraulic Filter Press

The hydraulic filter press has a wide range of applications in various industries. In the chemical industry, it is used to filter chemicals and remove impurities. In the petrochemical industry, it is used to filter oil and remove impurities.

In the pharmaceutical industry, it is used to filter drugs and remove impurities. In the food and beverage industry, it is used to filter liquids and remove impurities, ensuring the quality of the final product.

Benefits of Hydraulic Filter Press

The hydraulic filter press offers several benefits, including:

-

High filtration efficiency

-

Versatility in application

-

Easy to operate and maintain

-

Cost-effective solution

-

Ideal for applications where high purity is required