Skip to content

Plate and Frame Filter Press: This is the most common type of filter press, consisting of a series of plates and frames that separate solids from liquids.

Membrane Filter Press: This type of filter press uses a thin, flexible membrane instead of plates and frames. The membrane is made of polypropylene or polyester, and it is designed to filter out finer particles than plate and frame filter presses.

Cartridge Filter Press: This type of filter press uses a cartridge-type filter element, which is made of pleated paper or synthetic material.

Candle Filter Press: This type of filter press uses a cylindrical filter element, which is made of pleated paper or synthetic material.

Automatic Filter Press: This type of filter press is equipped with automated controls and systems, which allow for continuous operation and minimal maintenance.

Posts Tagged: Types of Filter Press

Different Types of Filter Press

On January 19, 2024 by Megan Johnston With 0 Comments

- Blogging

Filter presses are an essential tool in various industries, including chemical processing, food and beverage, pharmaceuticals, and wastewater treatment. In this article, we will explore the different types of filter presses, their features, and their applications.

Types of Filter Press

There are several types of filter presses, each with its unique characteristics and uses. The most common types of filter presses include:

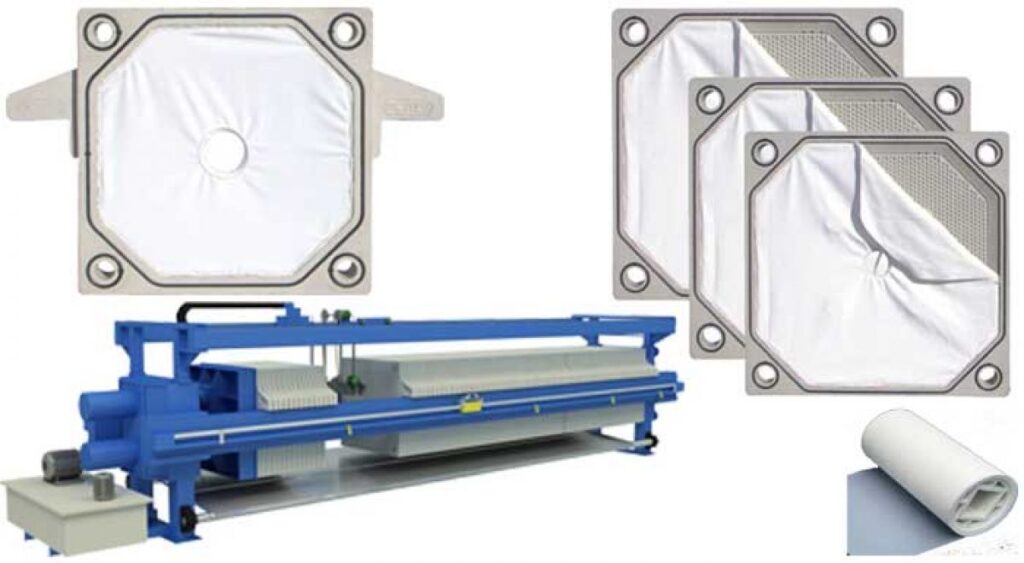

Plate and Frame Filter Press: This is the most common type of filter press, consisting of a series of plates and frames that separate solids from liquids.

The plates are made of metal or polypropylene, and the frames are made of metal or plastic. This type of filter press is used in various industries, including chemical processing, food and beverage, and wastewater treatment.

Membrane Filter Press: This type of filter press uses a thin, flexible membrane instead of plates and frames. The membrane is made of polypropylene or polyester, and it is designed to filter out finer particles than plate and frame filter presses.

Membrane filter presses are commonly used in applications where high purity is required, such as in the production of pharmaceuticals.

Cartridge Filter Press: This type of filter press uses a cartridge-type filter element, which is made of pleated paper or synthetic material.

The cartridge is designed to filter out particles and impurities from the liquid, and it can be easily replaced when it becomes clogged. Cartridge filter presses are commonly used in applications where space is limited, such as in laboratories or pilot plants.

Candle Filter Press: This type of filter press uses a cylindrical filter element, which is made of pleated paper or synthetic material.

The candle filter press is designed to filter out particles and impurities from the liquid, and it can be used in various industries, including chemical processing, food and beverage, and wastewater treatment.

Automatic Filter Press: This type of filter press is equipped with automated controls and systems, which allow for continuous operation and minimal maintenance.

Automatic filter presses are commonly used in large-scale industrial applications where high productivity and low maintenance are required.

Applications of Filter Presses

Filter presses have a wide range of applications in various industries, including:

Chemical Processing: Filter presses are used to separate solids and liquids in chemical processing applications, such as in the production of chemicals, pharmaceuticals, and fuels.

Food and Beverage: Filter presses are used to filter out impurities and contaminants from food and beverage products, such as fruit juice, wine, and dairy products.

Pharmaceuticals: Filter presses are used to filter out impurities and contaminants from pharmaceutical products, such as medicines and vaccines.

Wastewater Treatment: Filter presses are used to separate solids and liquids in wastewater treatment applications, such as in the treatment of industrial wastewater and domestic wastewater.

Benefits of Filter Presses

Filter presses offer several benefits, including:

High Filtration Efficiency: Filter presses can filter out particles and impurities with high efficiency, resulting in a high-quality product.

Low Maintenance: Filter presses are designed to be easy to maintain, with few moving parts and a simple design.

Continuous Operation: Filter presses can operate continuously, allowing for high productivity and minimal downtime.

Versatility: Filter presses can be used in a wide range of applications, making them a versatile tool in various industries.